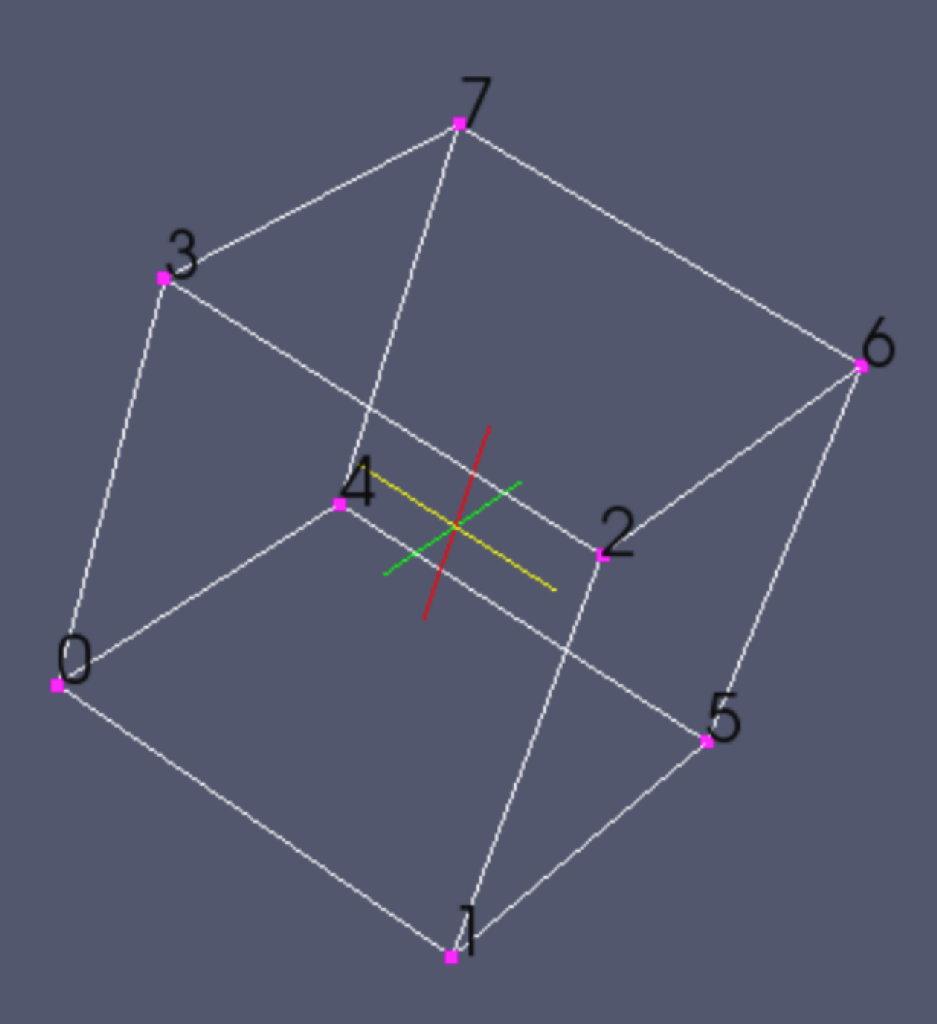

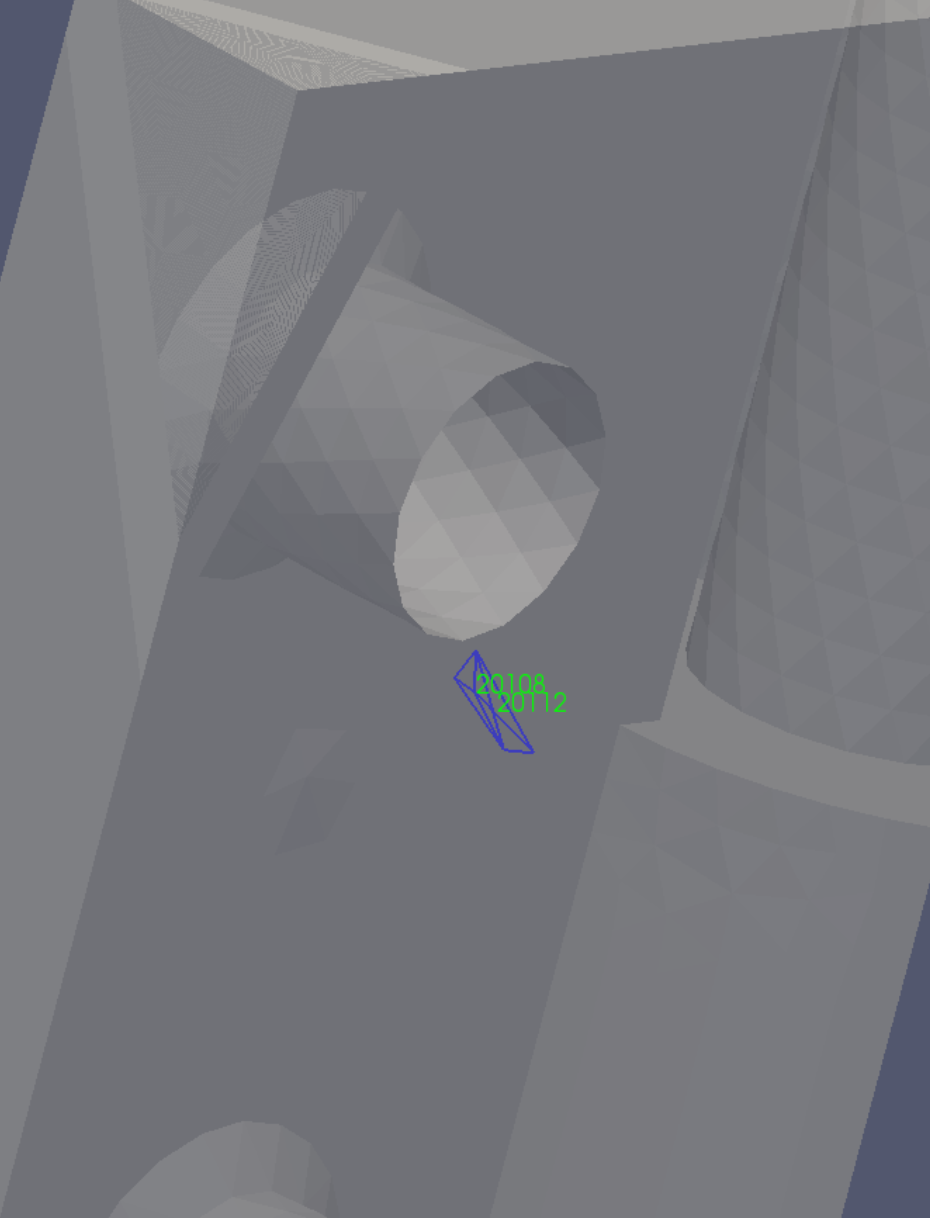

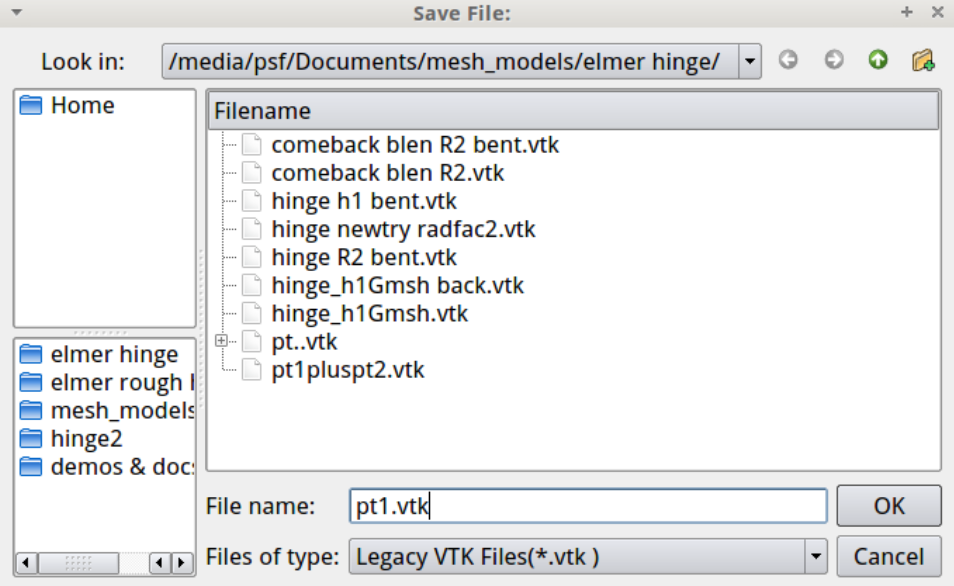

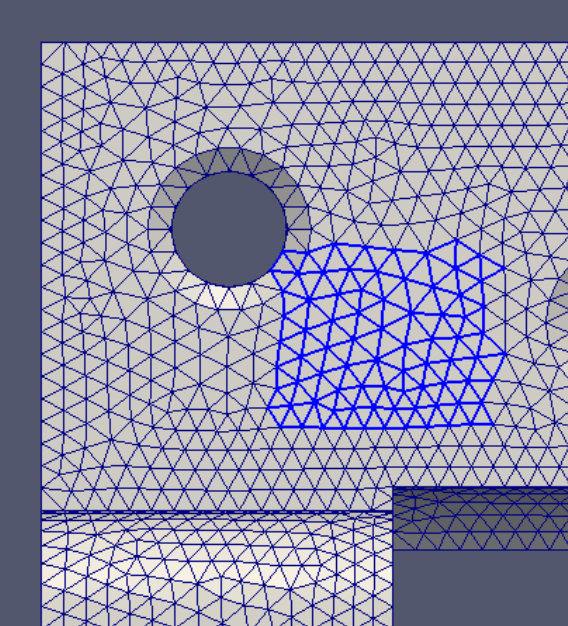

The pic to the right

shows the way that Lifted works. The center node is shared by a

number of elements, whose edges are seen here as radial lines. A

polygon of points, here a twice subdivided ico-sphere consisting

of 42 points, is created around the central node. A circuit is

made in which a trial move of the central point places it

sequentially at each of the ico points, and a quality attribute is

evaluated there. The conditions represented by each position are

analyzed and saved. Then, if the average quality of the entire

group of elements improves when the point is located at the most

favorable trial position, that position is retained, and another

vertex point (usually the worst case) is considered.

|

|

|

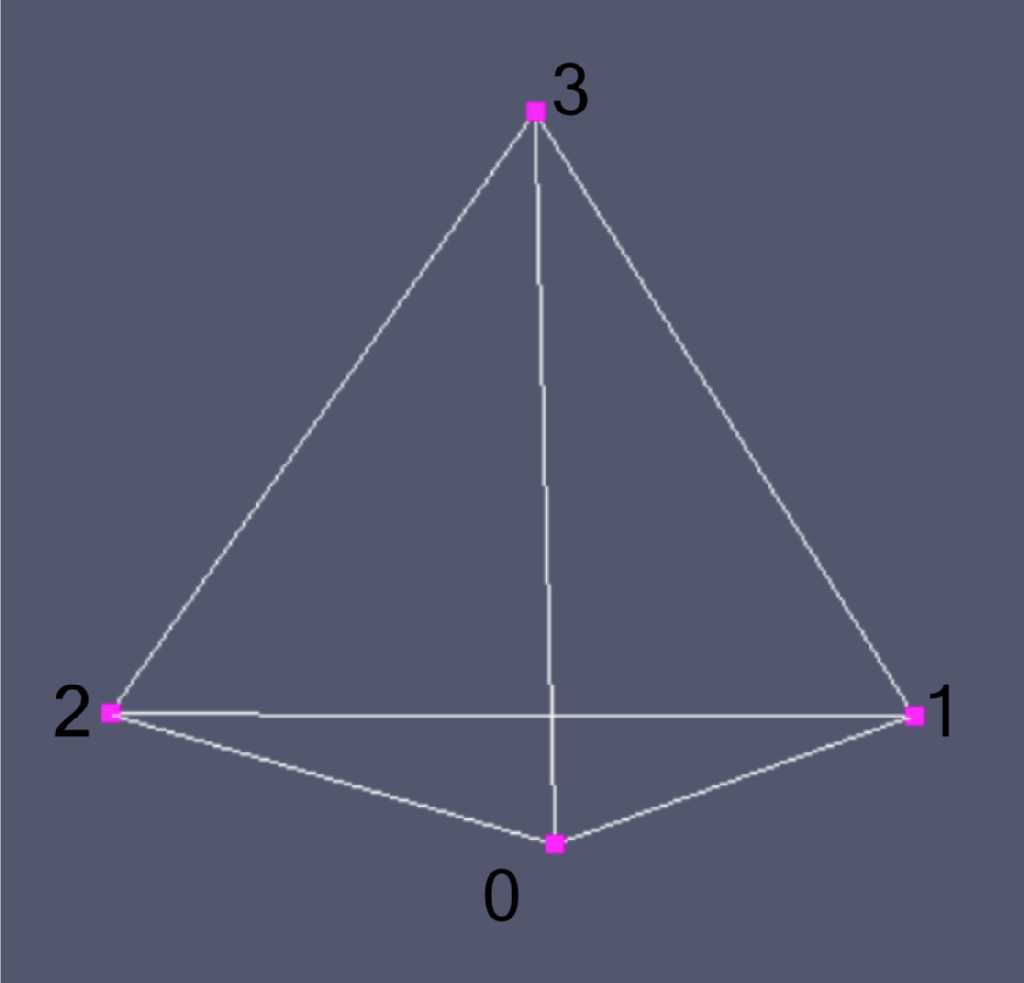

| At right is an

element with ordinary VTK node winding. Notice that (from the

outside) the numbering can go clockwise or counter-clockwise, and

that its outside direction reverses for the opposite face. This is

not satisfactory for Verdict winding however. The Verdict

requirement is for the first face listed to be wound clockwise. In

other words, for the cube pictured, the line 8 0 1 2 3 4 5 6 7

would not be acceptable to Verdict, whereas the line 8 4 5 6 7 0 1

2 3 would be acceptable. For tetrahedra the Verdict requirement

matches VTK. All VTK mesh which is opened by Lifted is rearranged,

if necessary, to enforce Verdict requirements. |

|

|

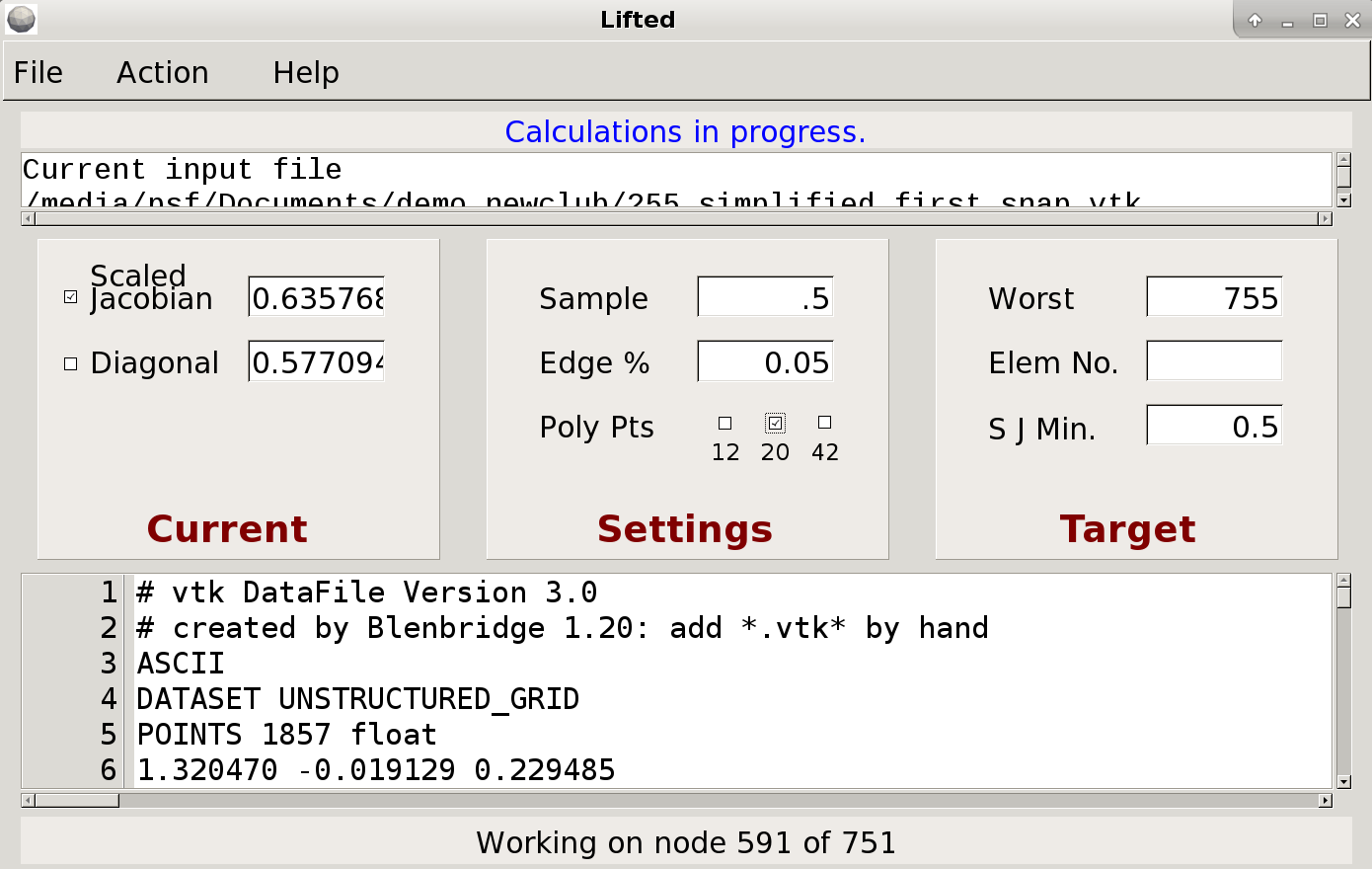

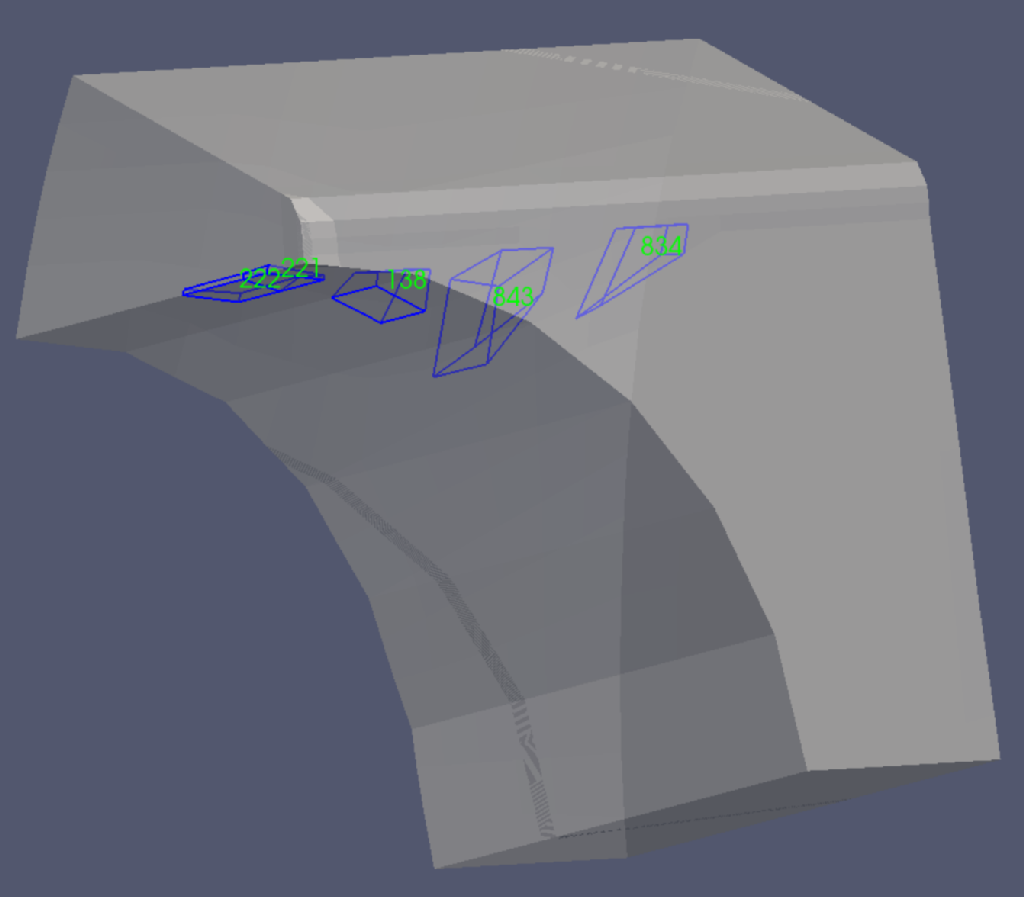

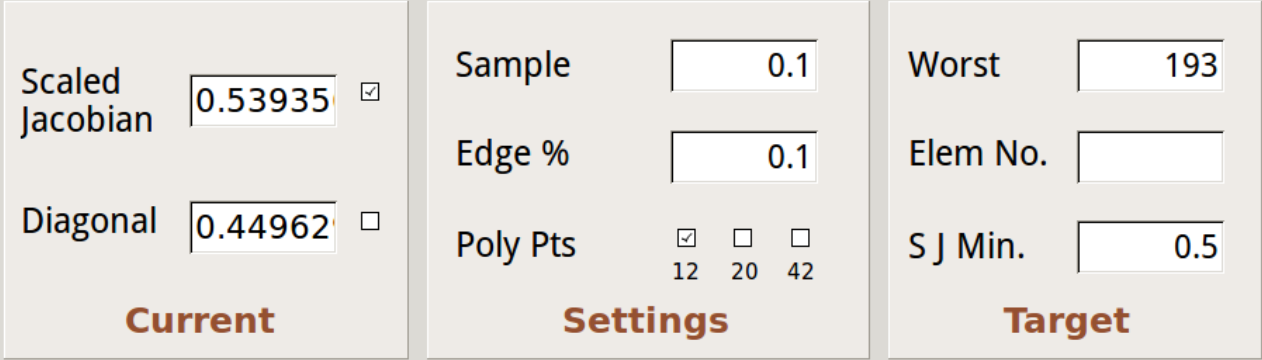

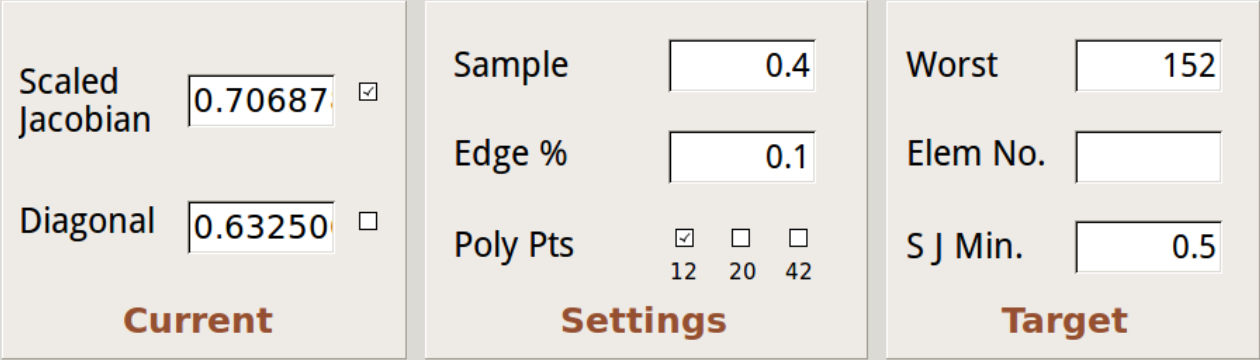

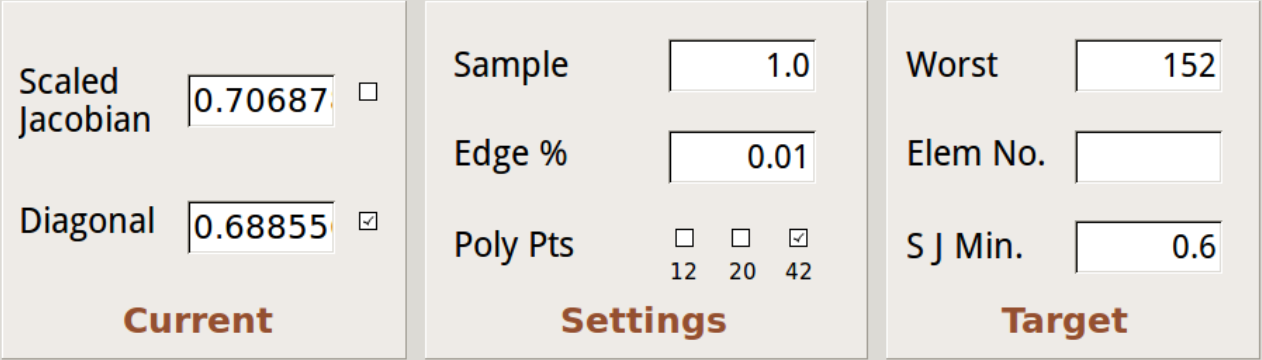

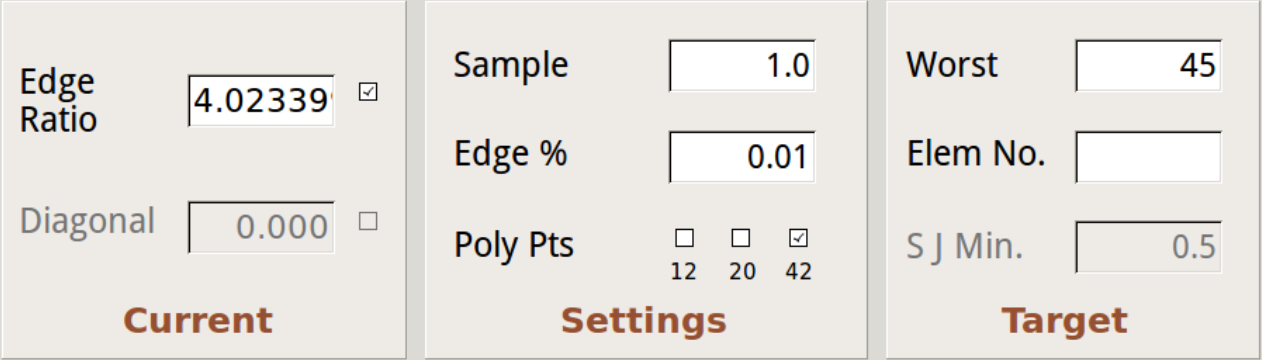

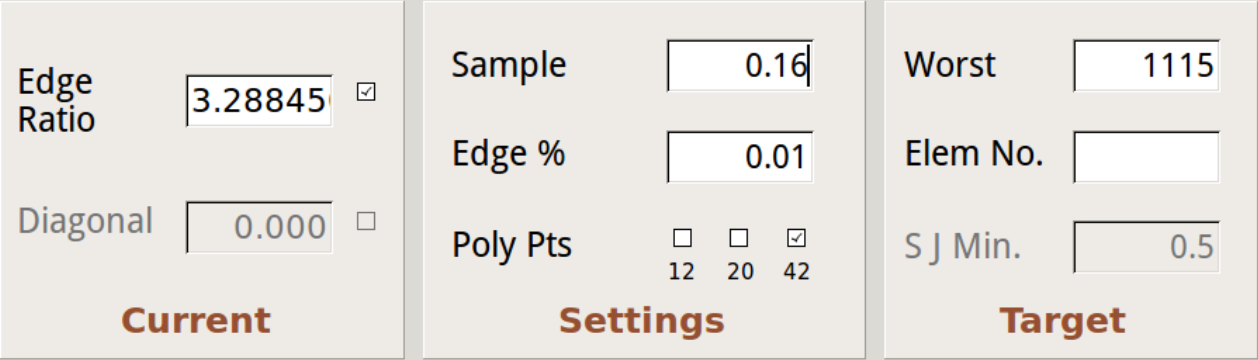

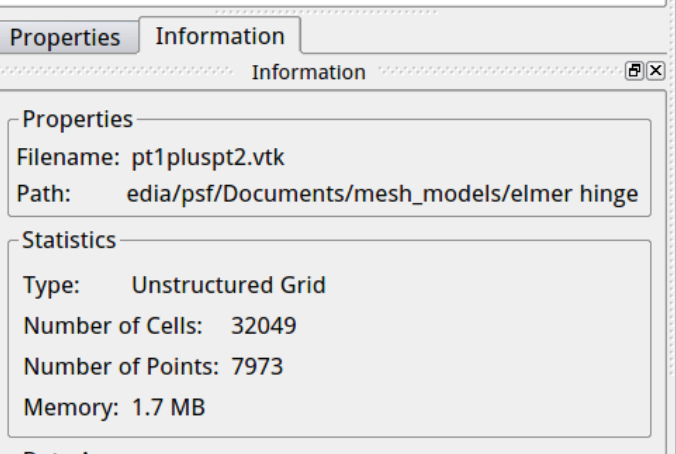

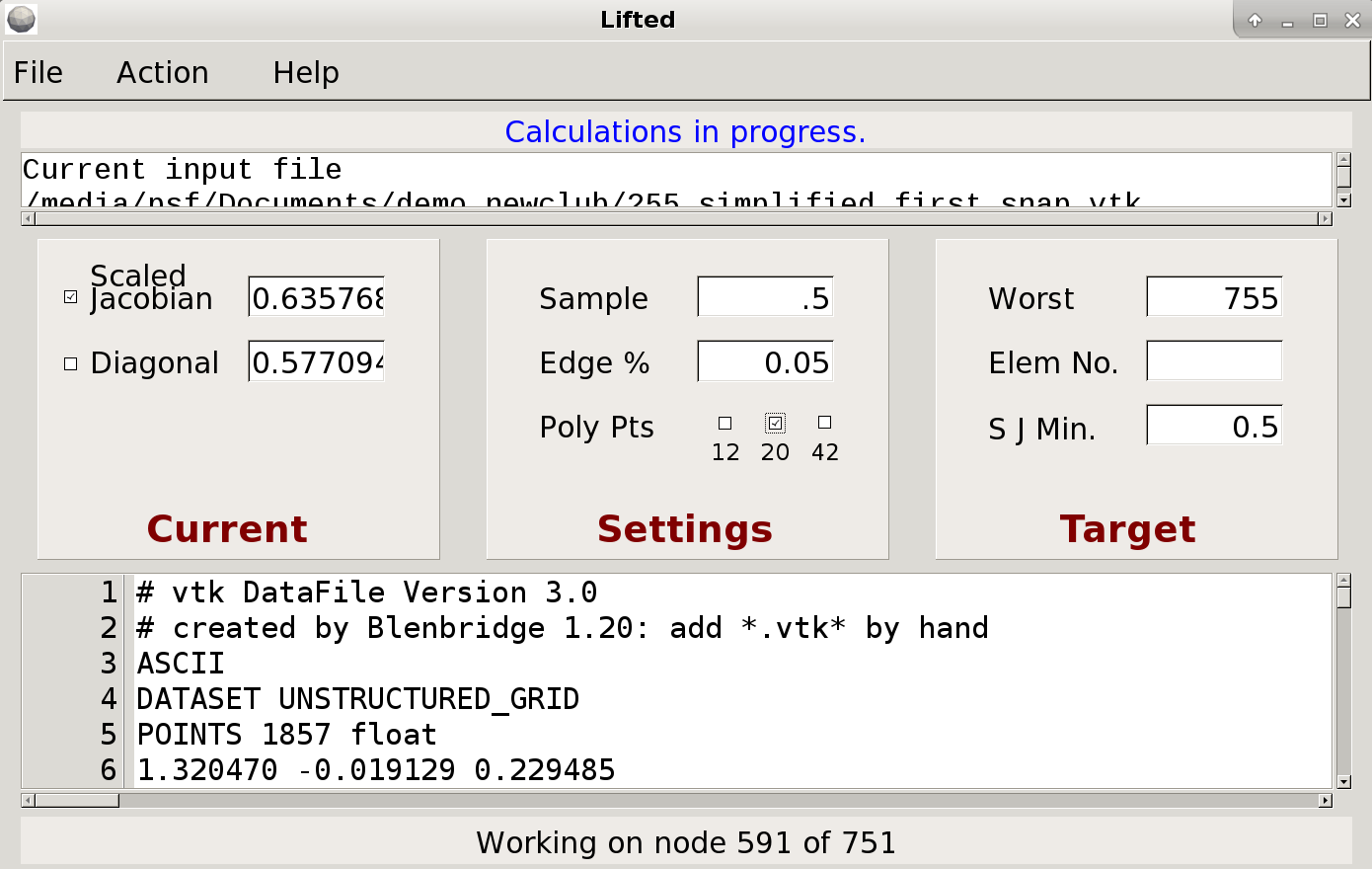

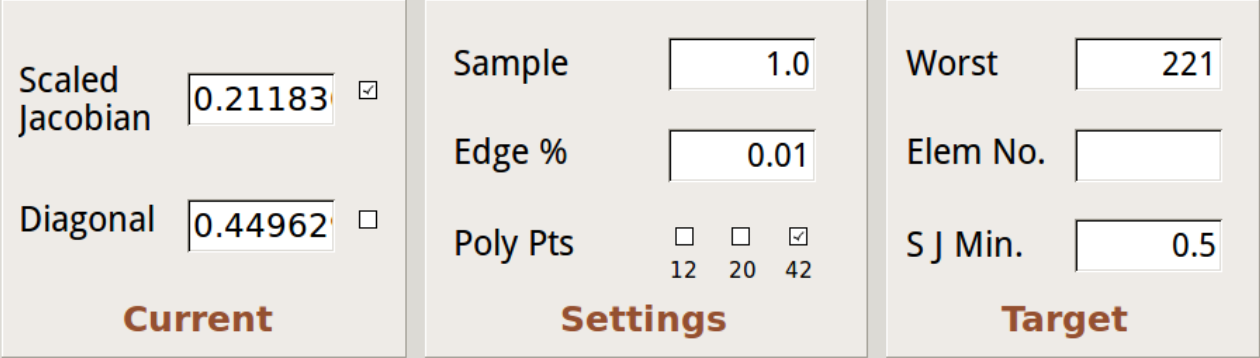

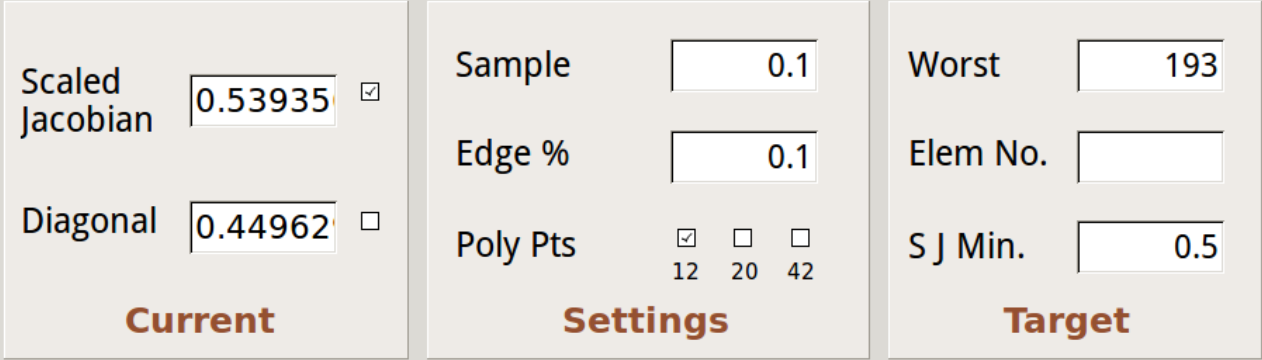

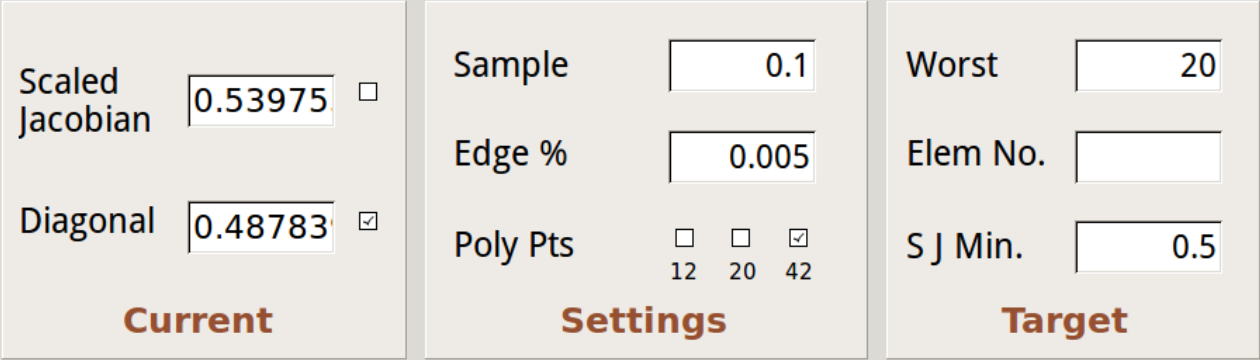

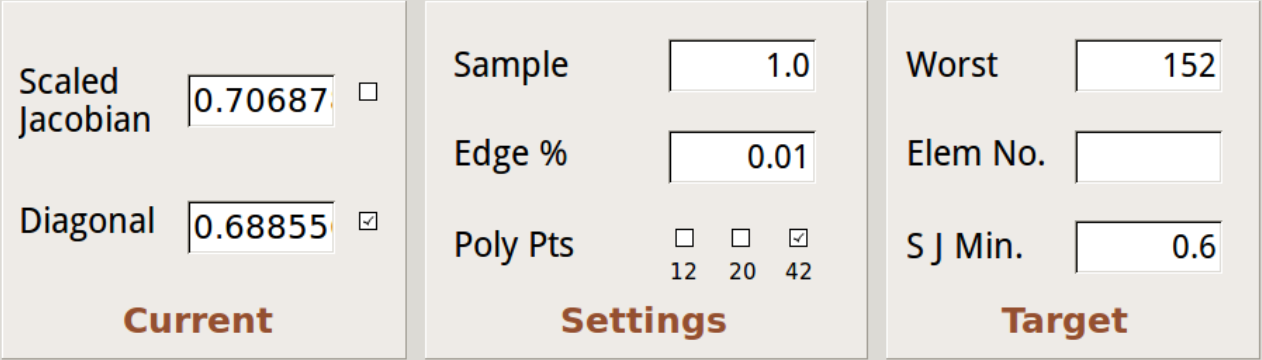

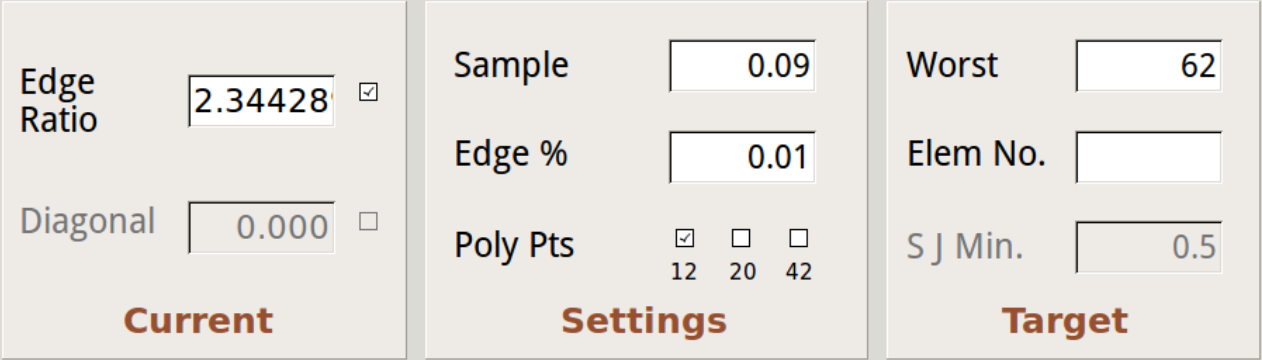

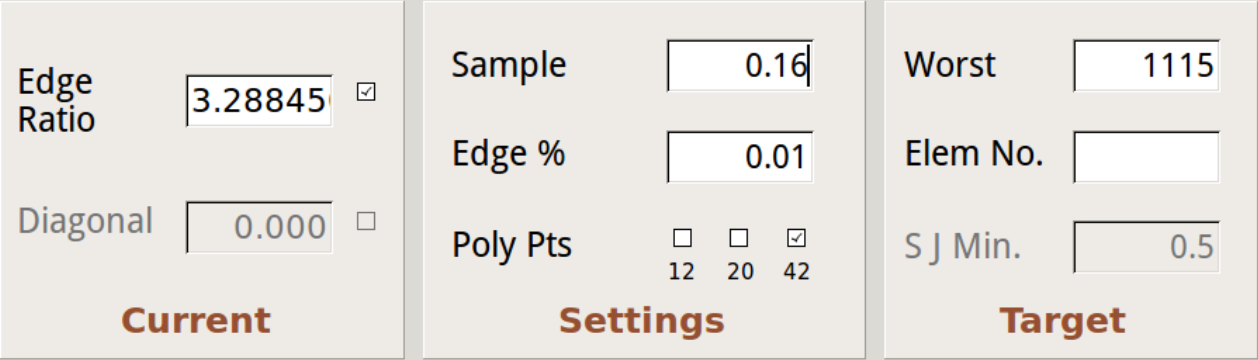

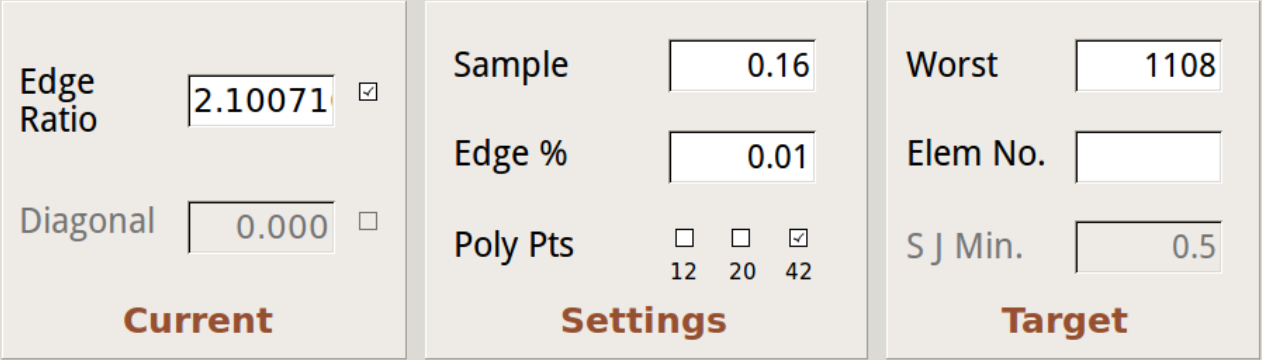

At right is the

U/I. On the ‘Current’ panel are located the two Verdict quality

standards used by Lifted, along with checkboxes to show which one

controls the current calculations. The ‘Settings’ panel governs

the geometrics of the trial positioning scheme. The ‘Target’ panel

displays the least conforming element, a text box for single

element treatment, and a quality guard factor. The Size button

maintains the preferred U/I size. Normal termination of the

Execute procedure is automatic, based on Sample size. However, a

Stop option in the Action menu is available if early termination

is desired. If saved immediately after selecting the Stop option,

the saved file will show the quality levels displayed at the time

of the stop.

|

|

|

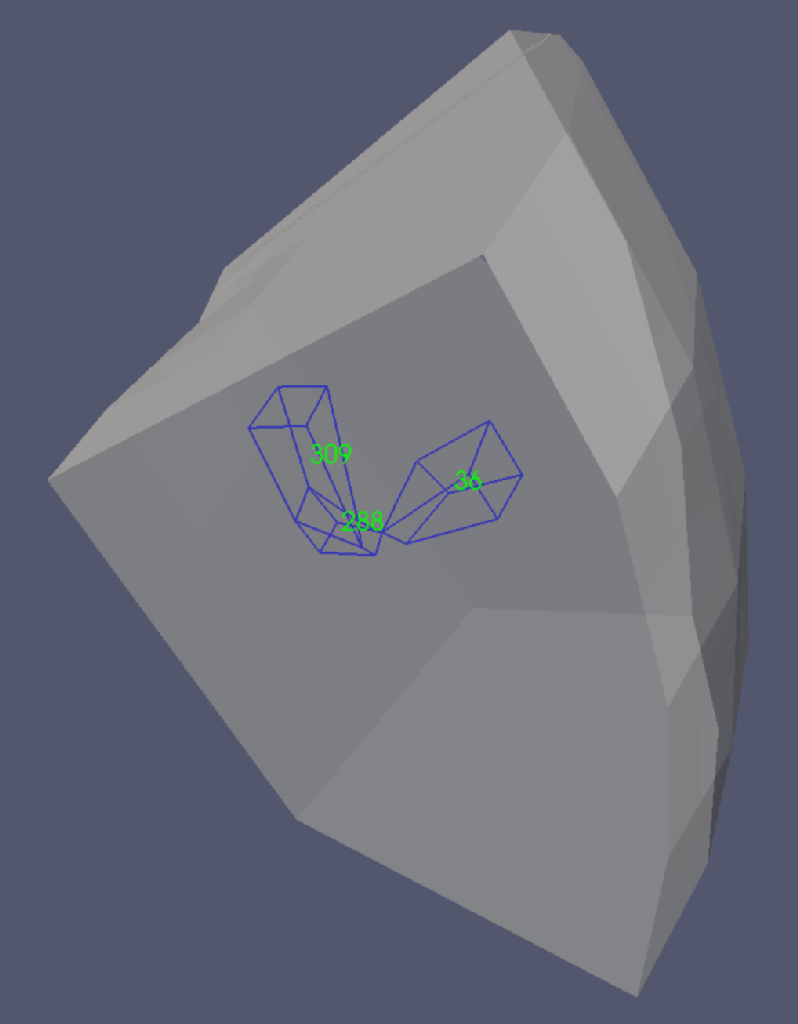

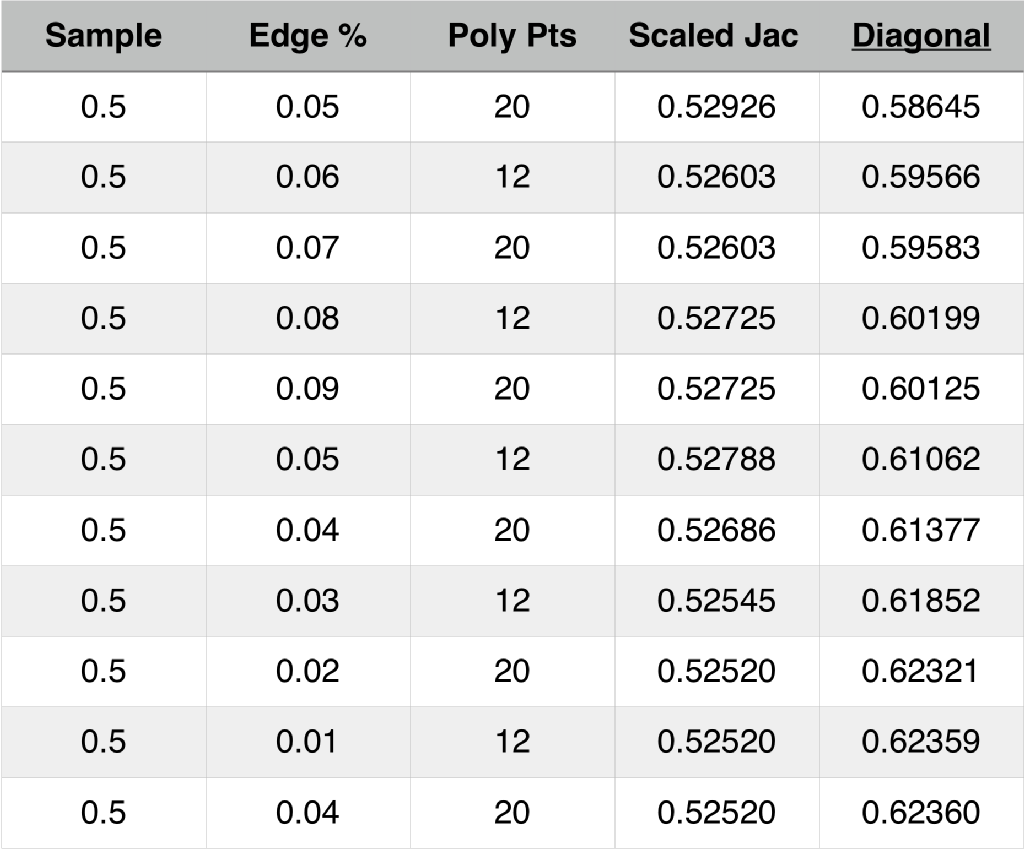

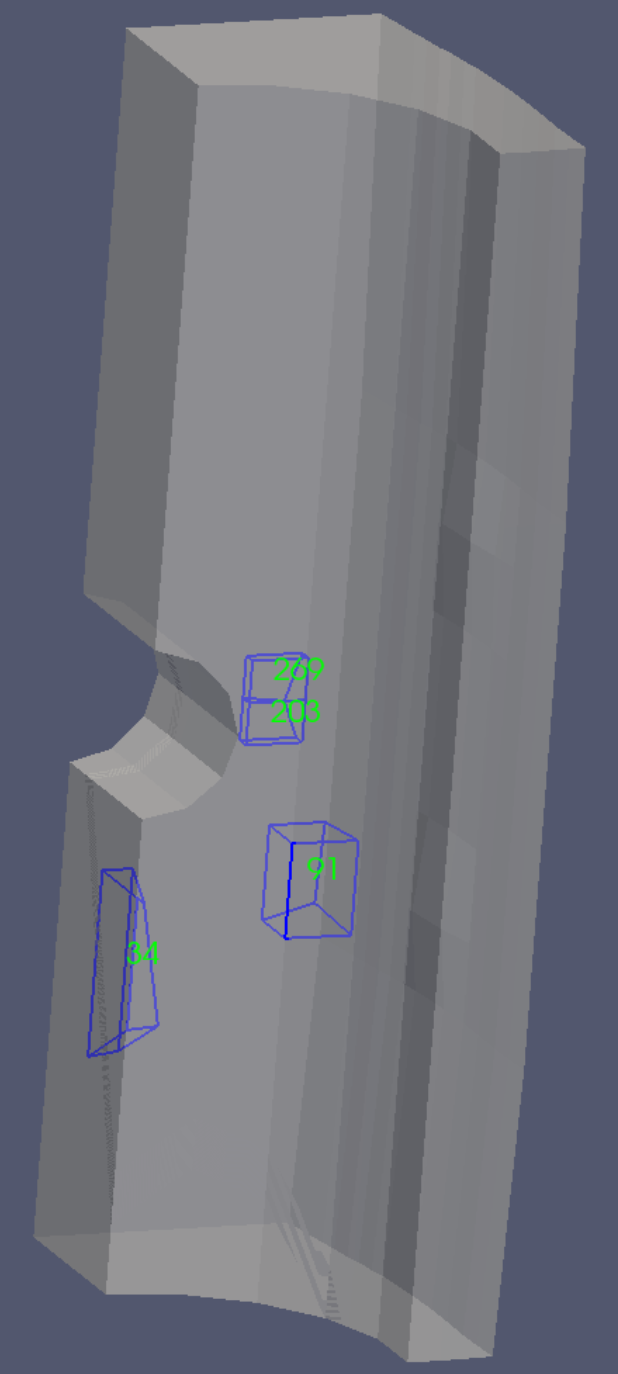

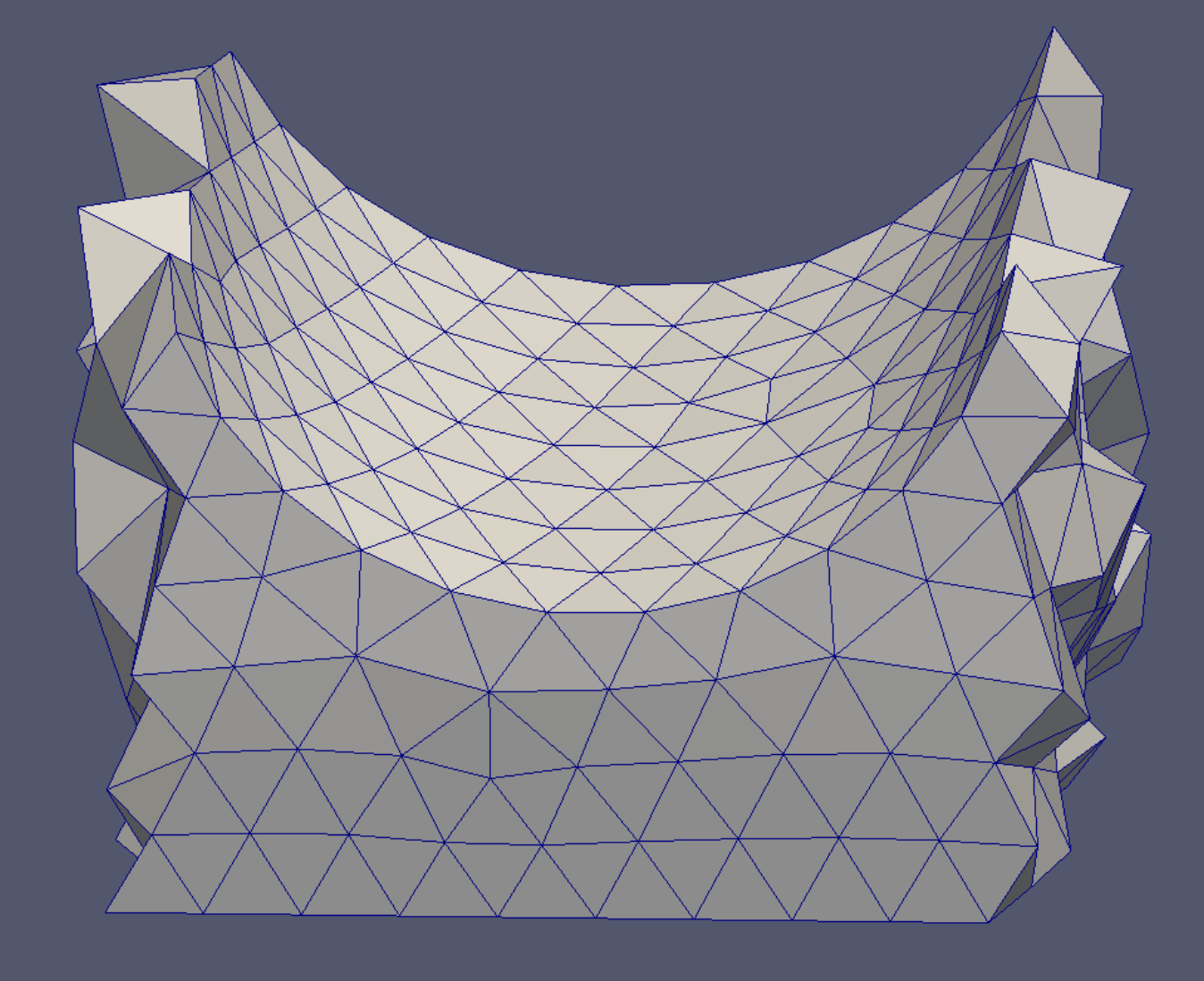

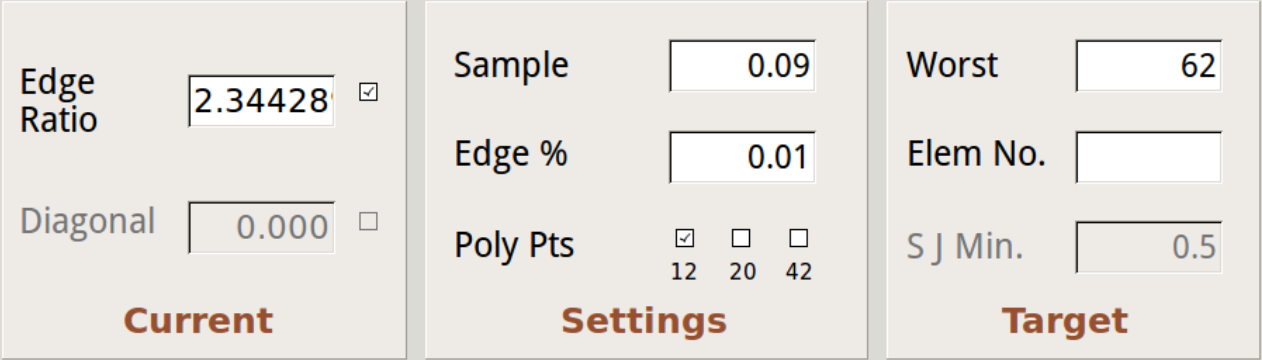

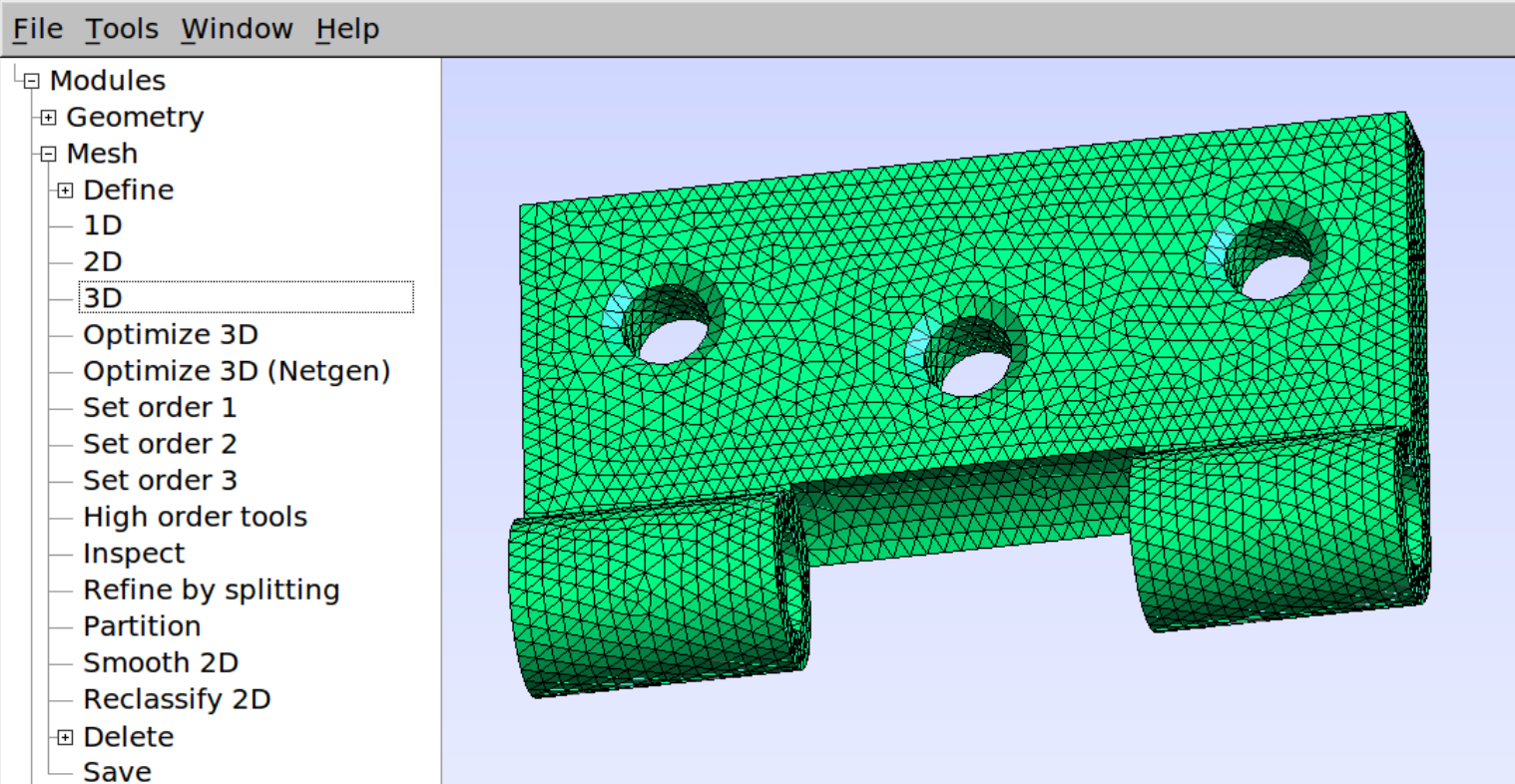

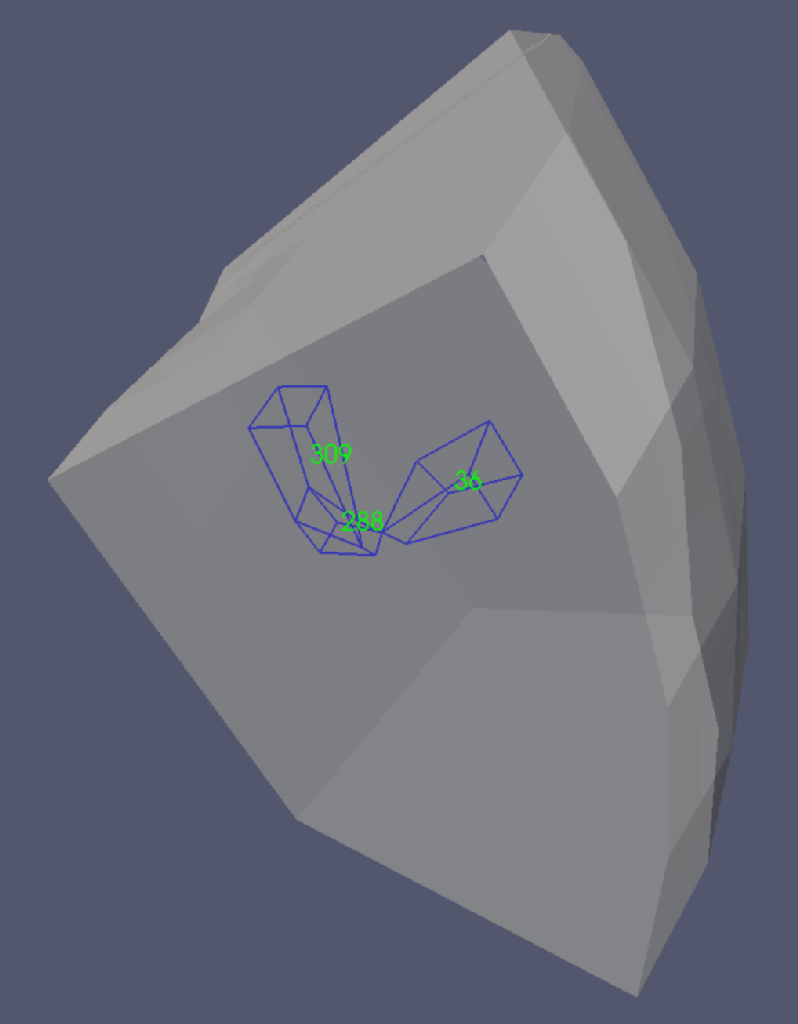

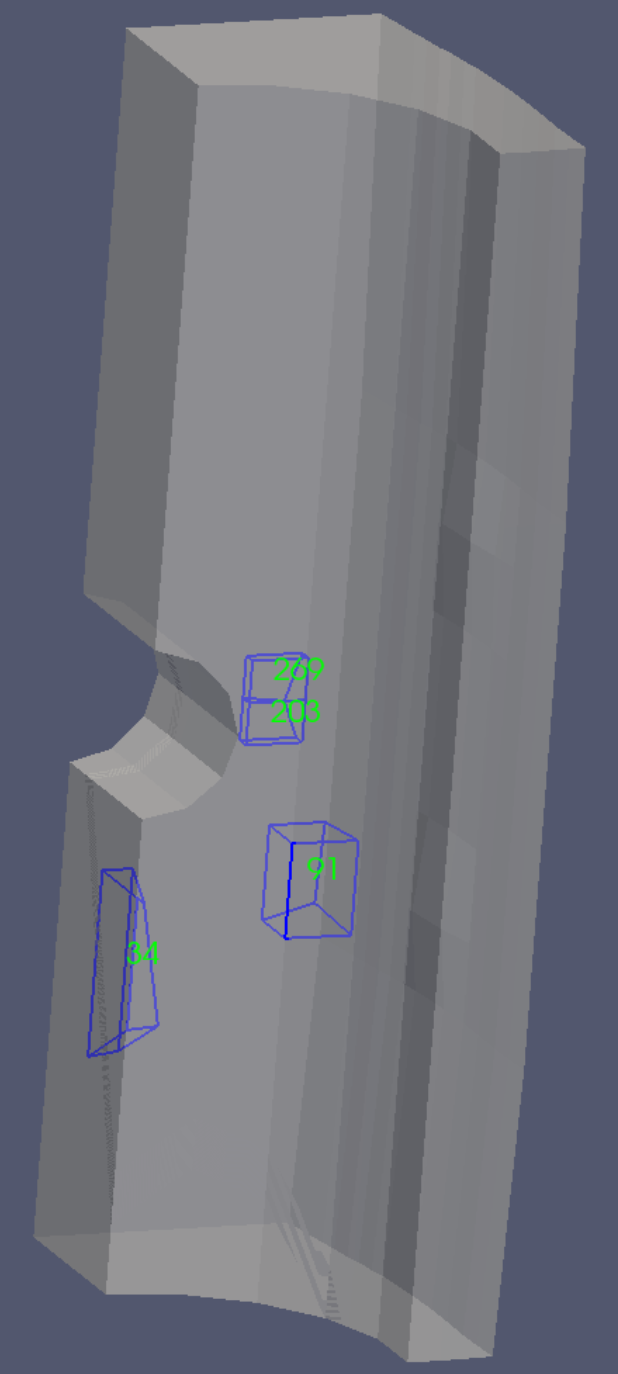

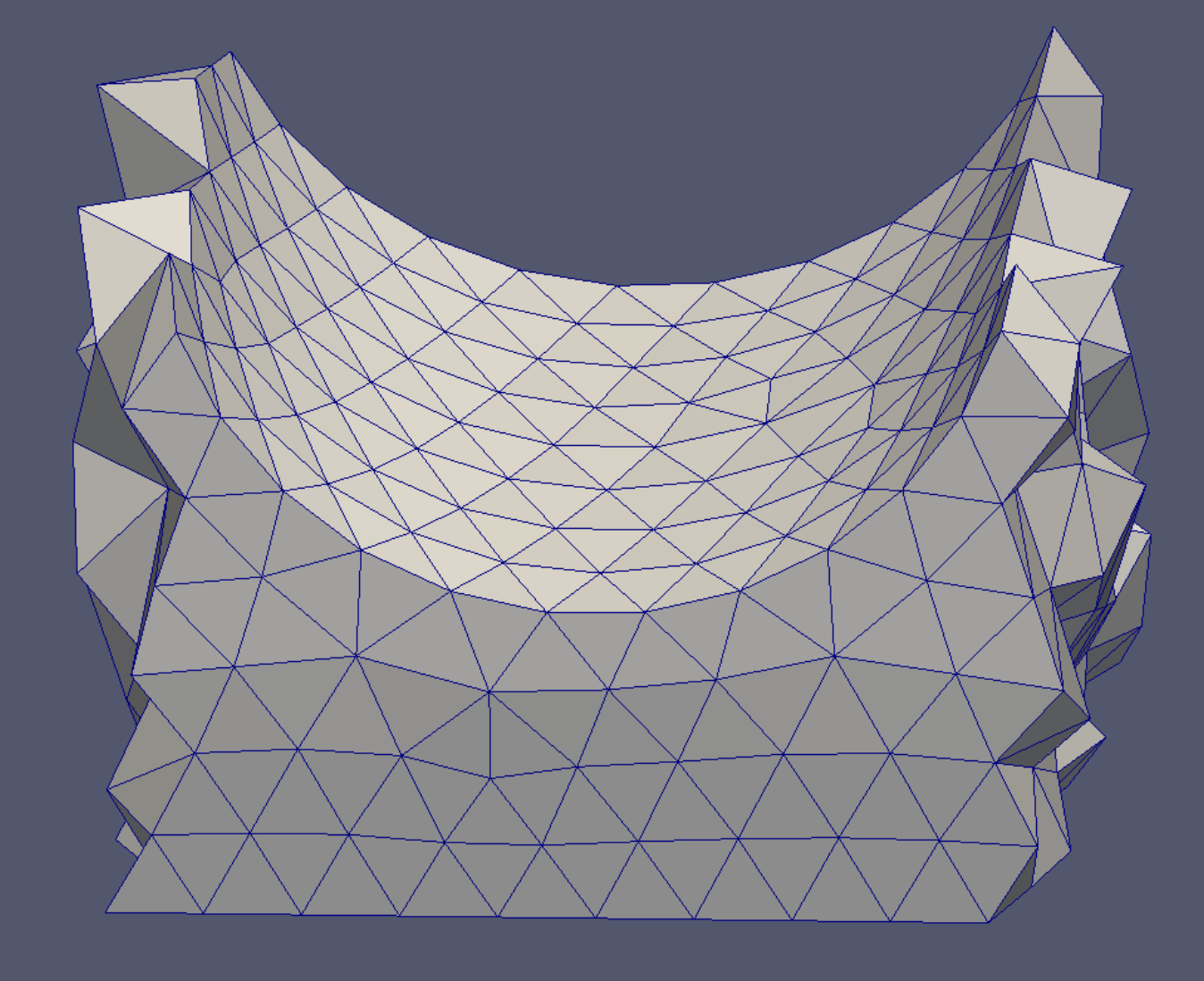

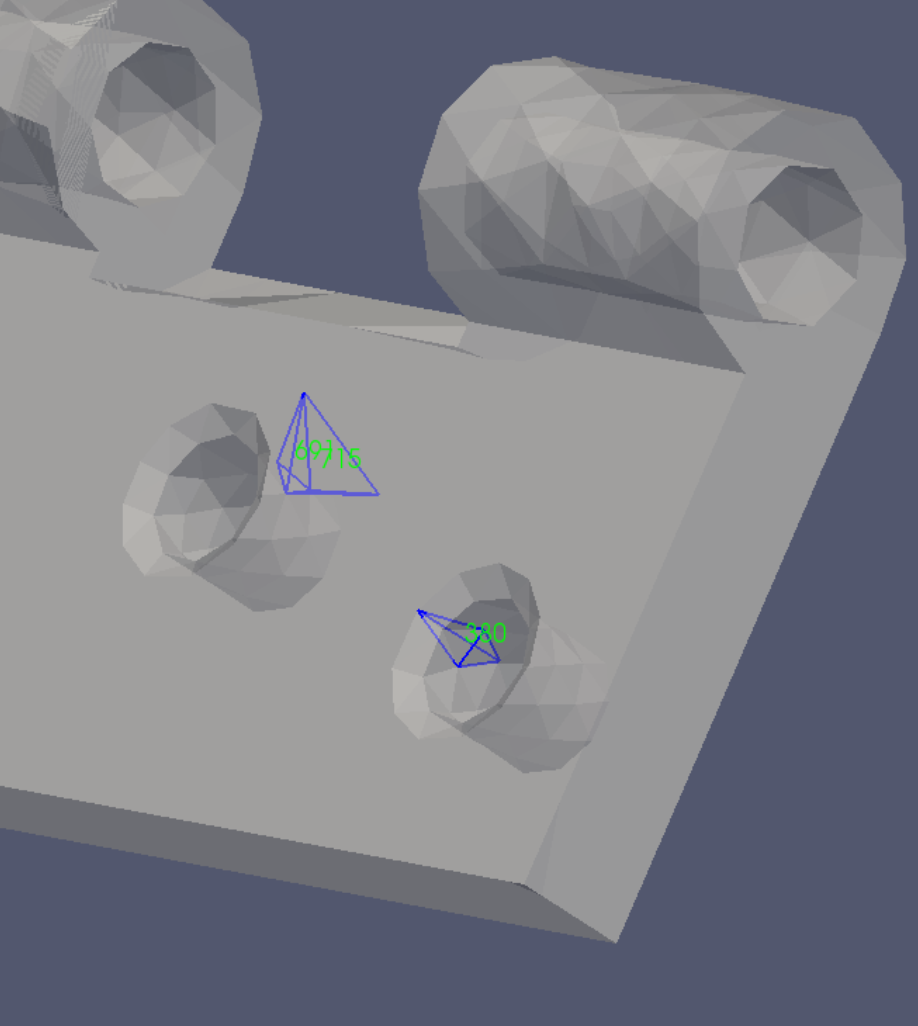

Demo 1

At right is shown the mesh for the first demo. It consists of a

chunk of 312 hex elements with a partly rounded exterior. Three of

its least regular elements are shown. Because none of the nodes

for these elements reside on the mesh surface, Lifted may be able

to accomplish a gain in quality. If, say, four nodes of a hex

element were located on the surface, Lifted could still operate on

the remaining internal nodes.

We note that although Lifted can work on both hexahedral and

tetrahedral mesh, the elements of the model must all be of the

same type. Additionally, elements must be of 1st Order. |

|

|

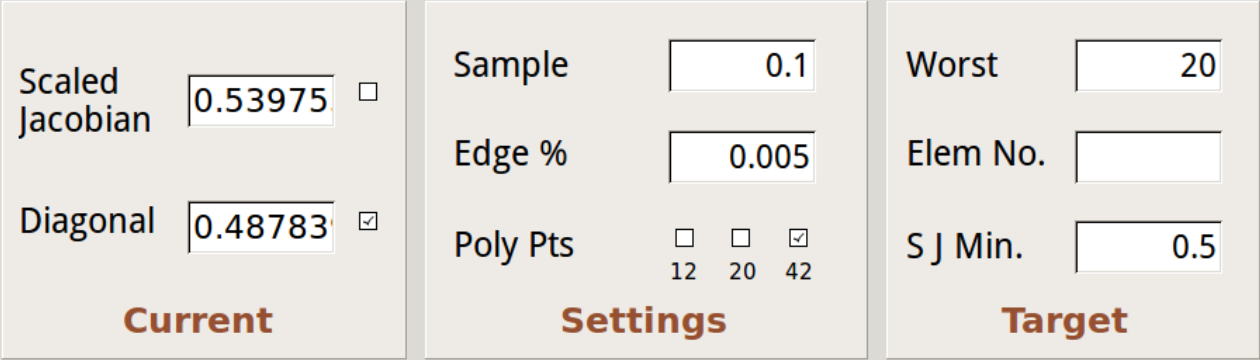

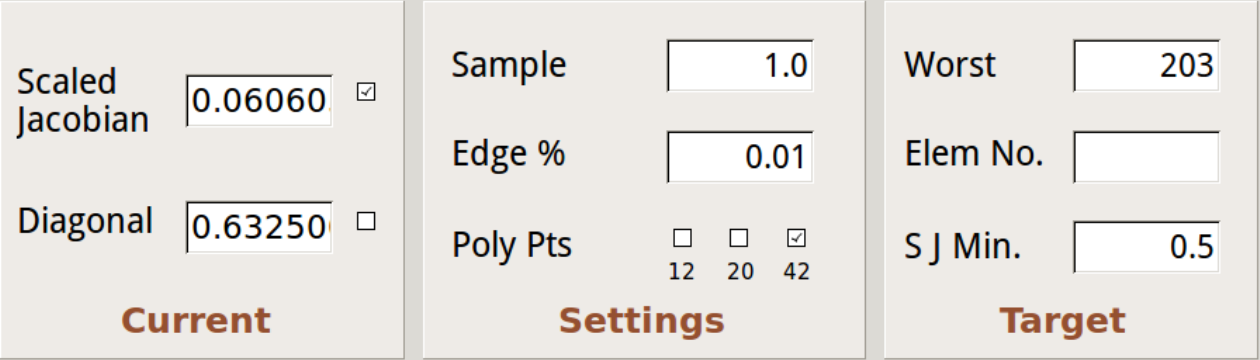

| In regard to the

U/I settings, the default Sample box factor of 1.0 means that the

number of samples considered is 1.0 times the number of elements

in the mesh. An excessive sample size does not hurt the results,

but wastes time. If the Current panel has locked into a static

display, but the node counter shown at the bottom of the U/I

during calculations still has a considerable number remaining, the

sample size is too big. If the ‘Current’ panel shows active change

throughout the run, the sample size may be, but is not

necessarily, too small. Generally, the larger the model, the

smaller the sample size multiplying factor needs to be. The Edge %

refers to the percent of the minimum edge length of the current

node used to define the ‘radius’ of the test polyhedron. The Poly

Pts checkboxes control the number of enclosed test points, making

up either a 12-, 20-, or 42-point polyhedron. |

|

|

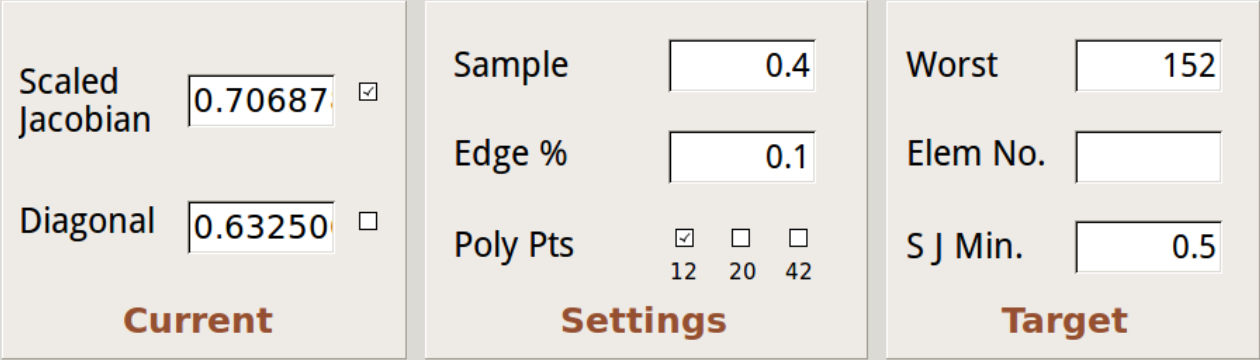

| Reaching a satisfactory

Scaled Jacobian value should suggest a save operation, to

establish a reusable base for exploring possible Diagonal

settings. |

|

|

The Verdict

standard for Scaled Jacobian of hexes is 0.5, and for Diagonal

measure it is 0.65.

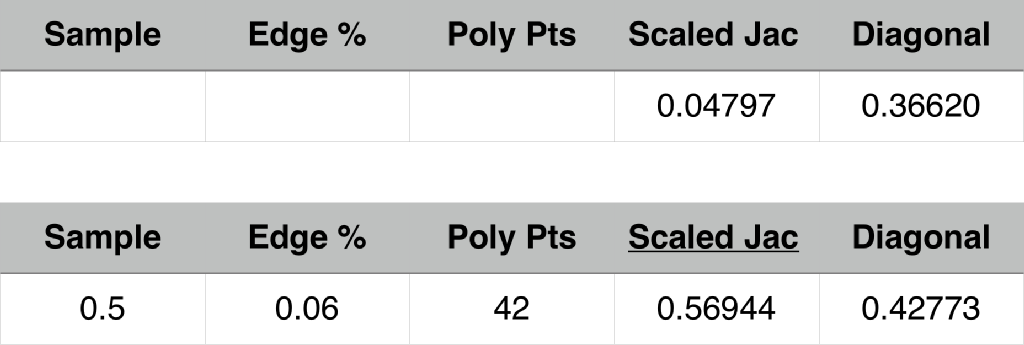

The top table above shows the Scaled Jacobian and Diagonal scores

of the demo file on opening. A single run with the Scaled Jacobian

checkbox checked, and settings as shown in the second table, gives

an improved value over the original. Then in the third table we

switch checkboxes and play with the Diagonal calculations. The

sequence of results in the Diagonal column shows an upward trend

in values, and the reader may perhaps see a suggestion of a kind

of method in the assignment of test values to Edge % and Poly Pts

parameters. However, we are presently unable to give a general

strategy for the best use of the fields. |

Demo 2

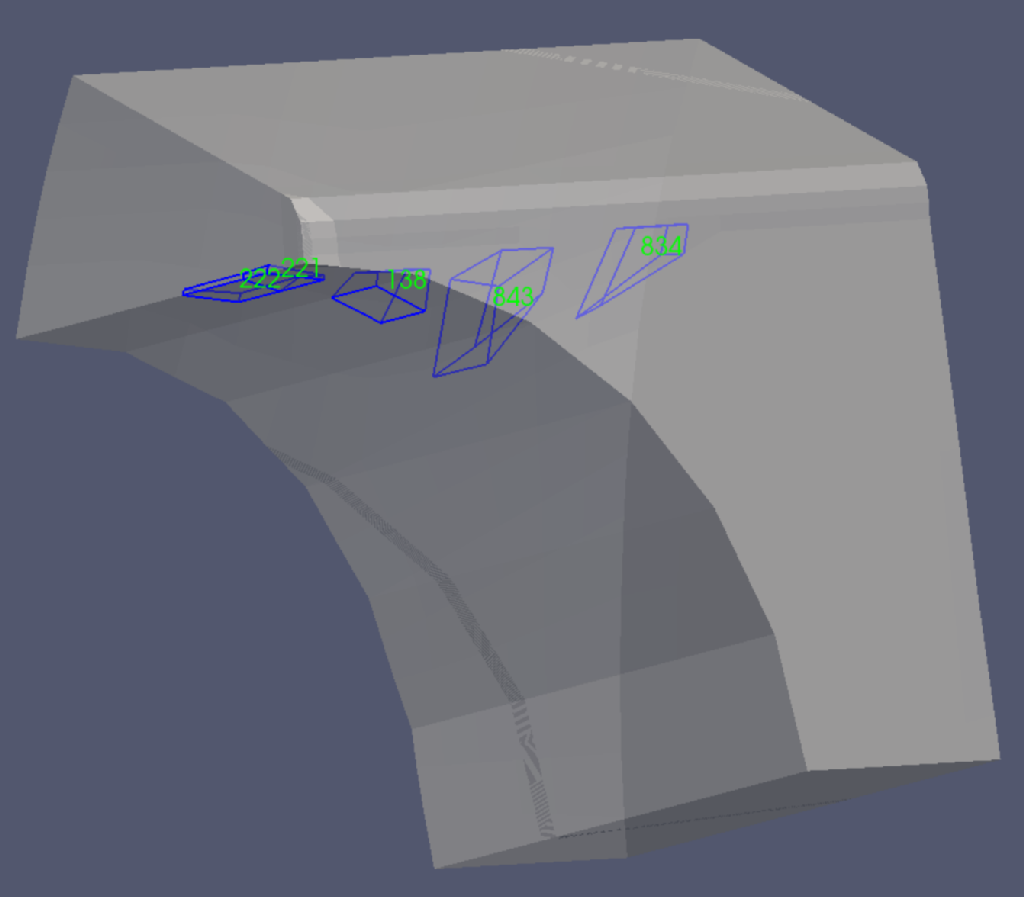

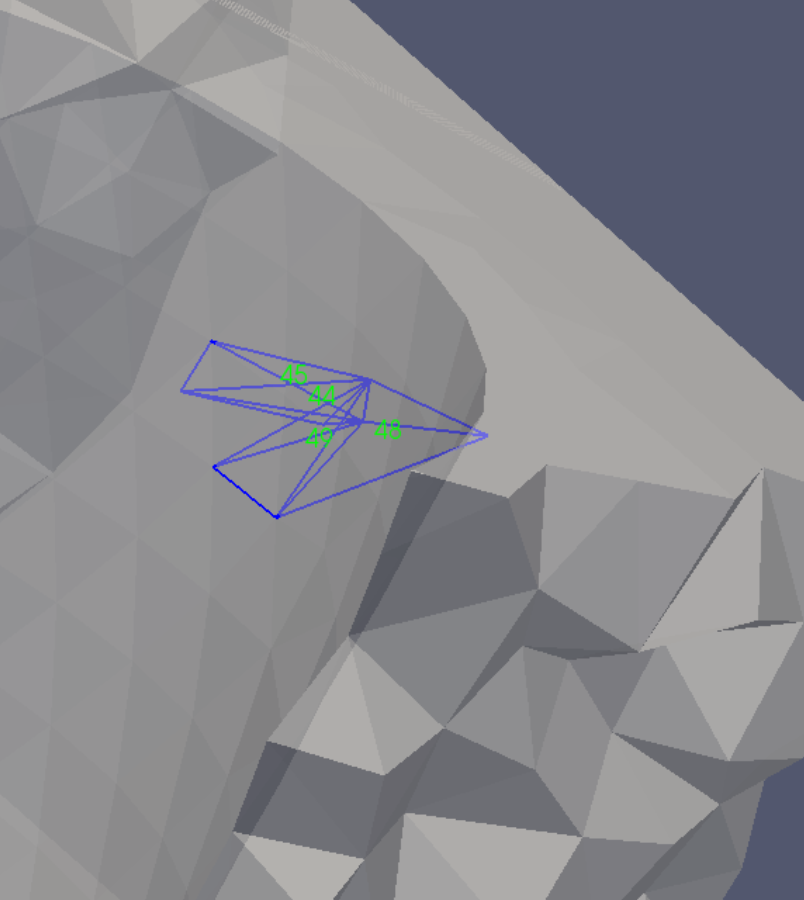

At right is shown the mesh for the second demo. It is a sort of

semi-arch of 912 hex elements. Five of its least regular elements

are illustrated, and the left three elements shown each have four

surface nodes. |

|

|

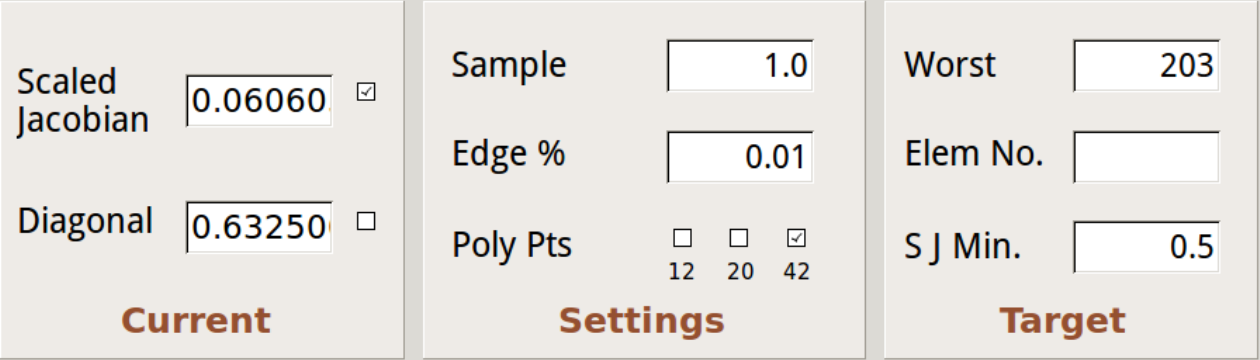

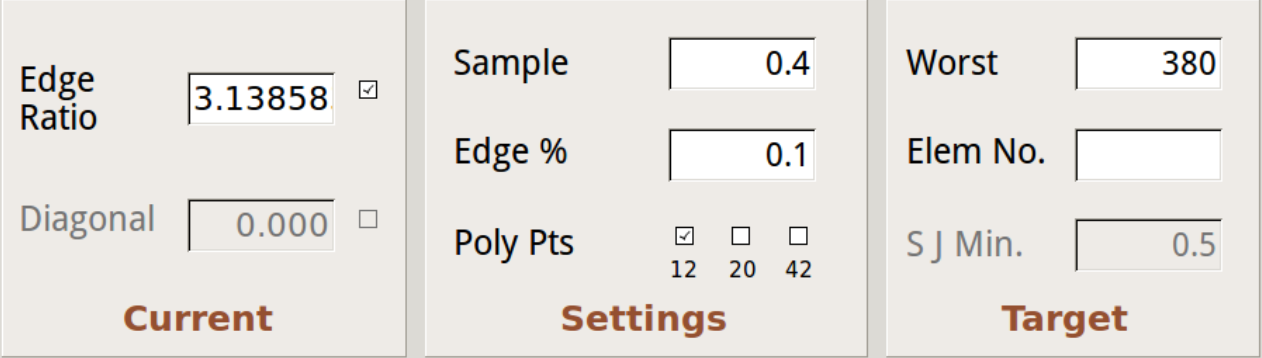

The top pic

shows the instrument board when the file is loaded. We understand

after a couple of trials that this file locks up fast, so there is

no need to retain a large sample. We also discover that the Scaled

Jacobian is not sensitive, and so we use a standard edge length

with a small polyhedron. Then we are ready to try to improve the

Diagonal. We find it resistant to change.

Incidentally, it may be time to comment on the SJ Min text block

in the Target panel. This value is the minimum Scaled Jacobian

which is allowed to appear as the Diagonal is calculated. It is

not fully dependable however, and may require some padding. Note

that Diagonal calculations will not start unless the current

Scaled Jacobian is equal to or greater than the current SJ Min. |

|

|

Demo 3

At right is shown the mesh for the third demo. It is a quarter

hole with a penetration, consisting of of 492 hex elements. Four

of its least regular elements are illustrated, and none contain

surface nodes.

A word about Lifted’s testing algorithm may be in order. A search

path is traveled twice, and in the first trip improvements are

sought for nonconforming elements, and the test results stored.

Scores are then sorted. At that point the initial conditions are

reset, and the number of iterations are conducted which produced

the highest score on the first half of the run, thus seizing the

optimal value for those settings.

If Lifted encounters a user-entered number in the Elem No edit

box, it calculates that element and then stops. This feature is

available for special effects, when the preferential sorting of

the auto Execute procedure is not desired, or to skip a stuck

element and do others. If the chosen element is not the worst

case, then the Status message at the top of the interface must be

relied on to inform the user whether or not processing the chosen

element results in improvement. |

|

|

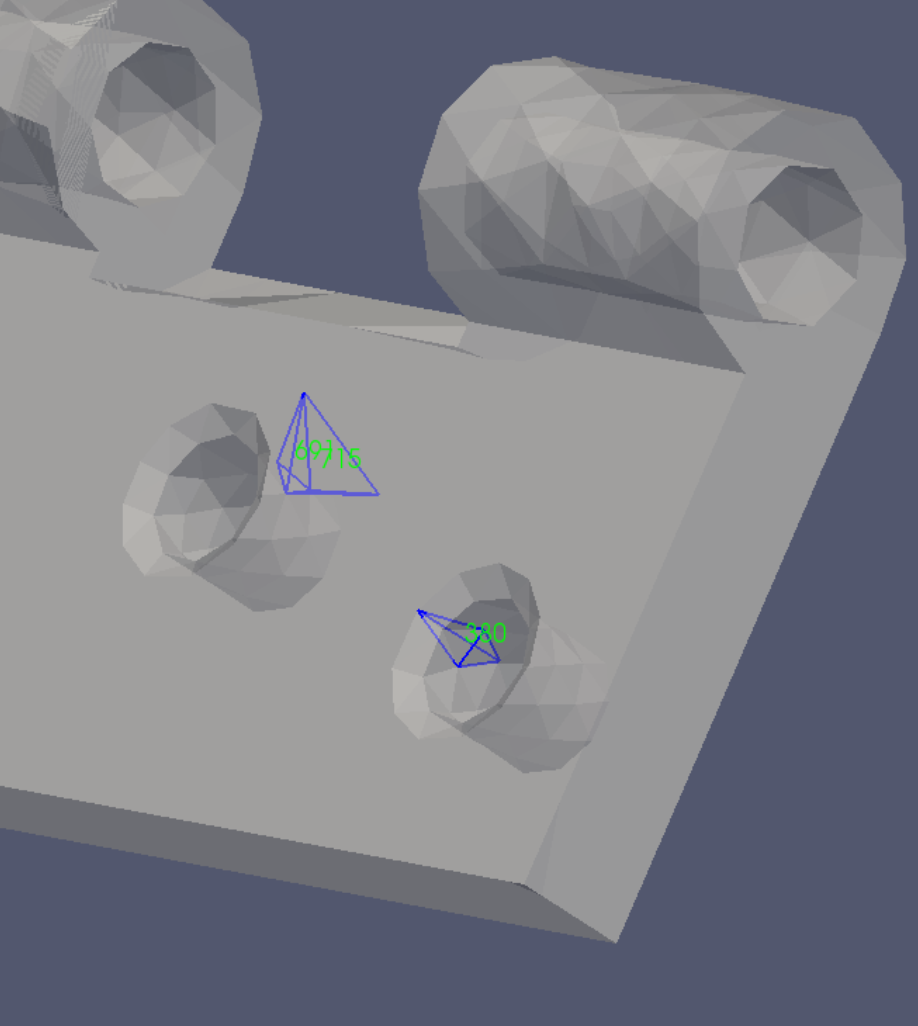

| The pictures at

right show some panels for the third demo. The second one shows

that it is easy to obtain a creditable Scaled Jacobian with this

mesh. A couple of trials demonstrate a high sensitivity when

calculating the Diagonal. Therefore we raise the SJ Min value to

protect the Scaled Jacobian, but find it an unnecessary precaution

when using the chosen settings. |

|

|

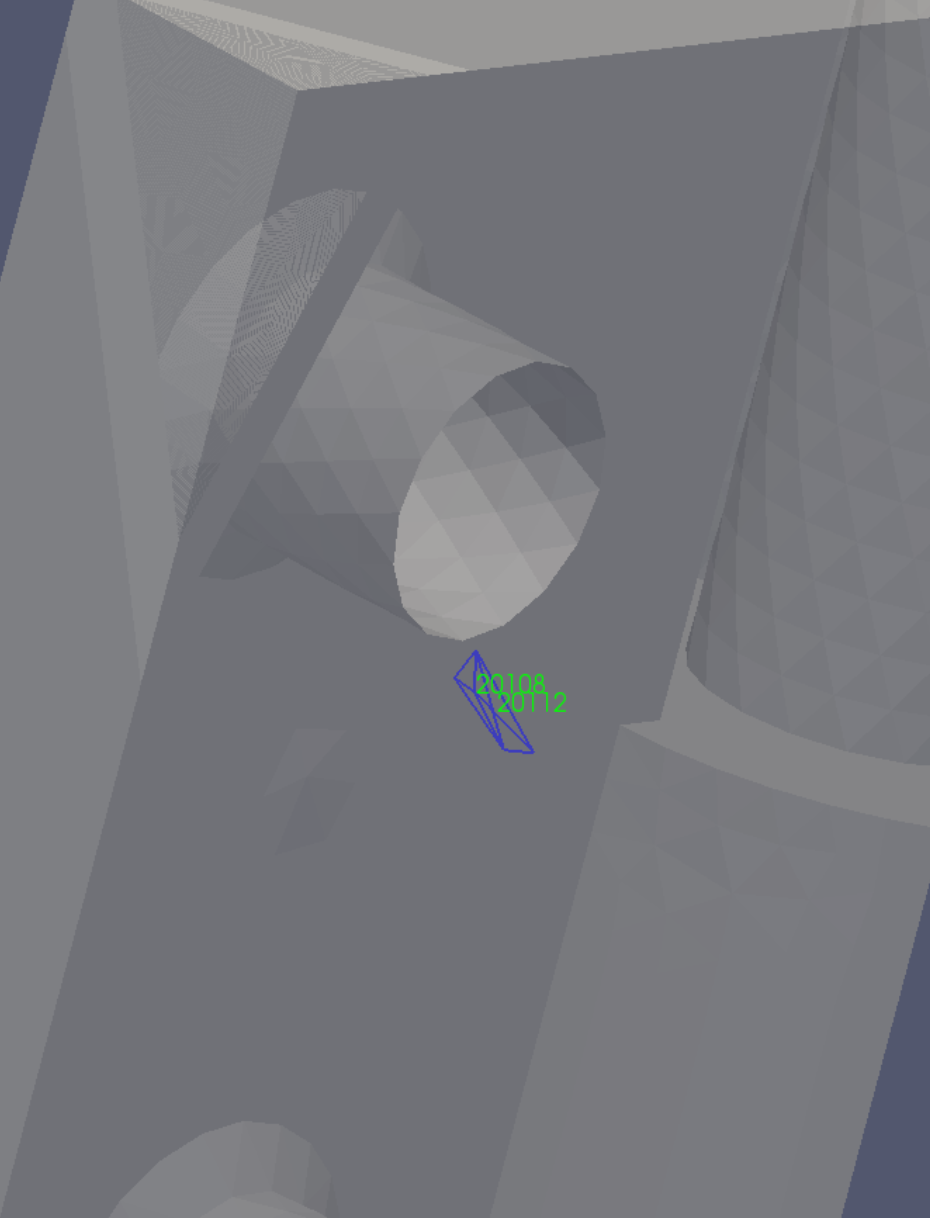

Demo 4

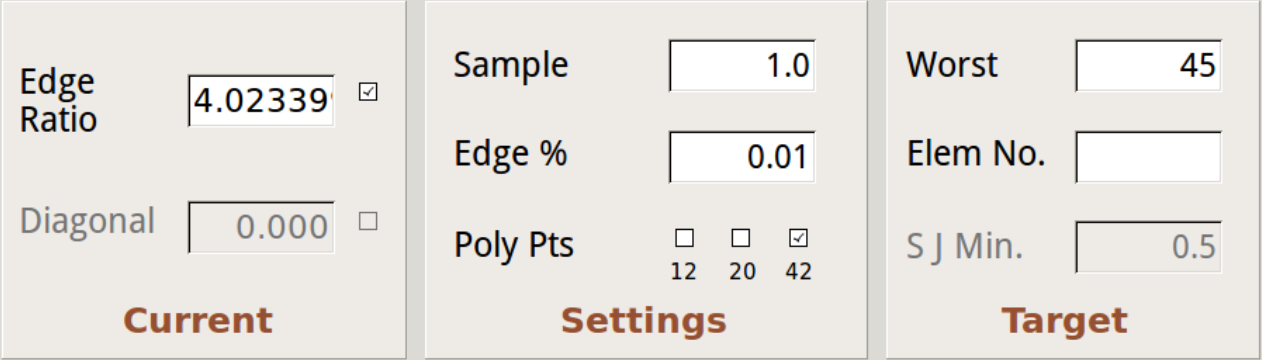

The pictures at right show the mesh for the fourth demo. It is a

cutaway of a journal housing, consisting of 1494 tetrahedral

elements. Four of the least conforming elements are shown lower

right. None of them contain a surface node. |

|

|

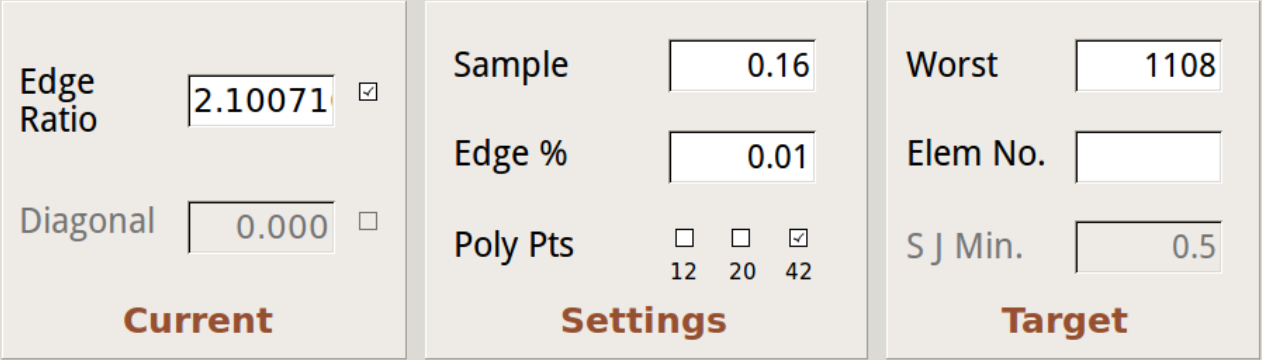

The picture at

right shows the Lifted panel upon opening the mesh

file. The

tetrahedral analysis involves fewer edit boxes than the hex

equivalent, and the unused ones are grayed out. The Verdict Edge

Ratio attribute is the only one we seek, and the acceptable

maximum level is judged to be 3.0.

The lower pic shows the edge ratio value achieved by the settings

depicted. We did not find settings which refined the results in

any successive trials, although we did find a few settings which

tied the outcome. |

|

|

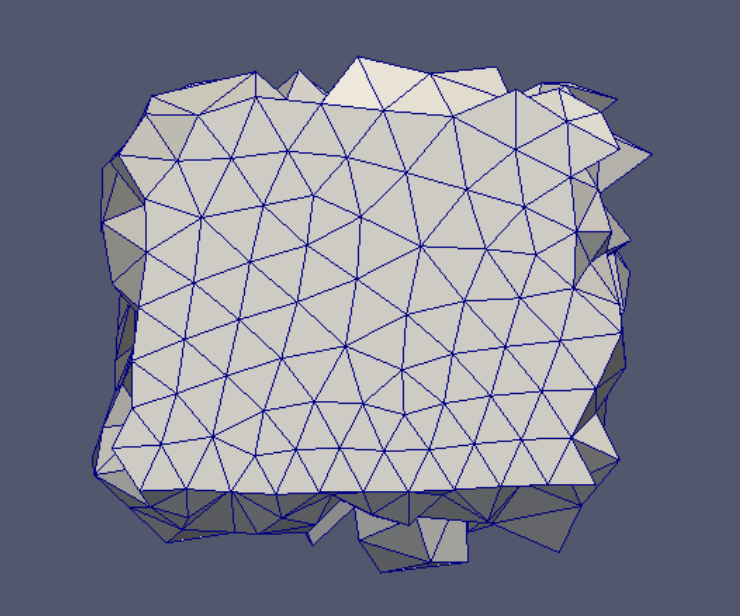

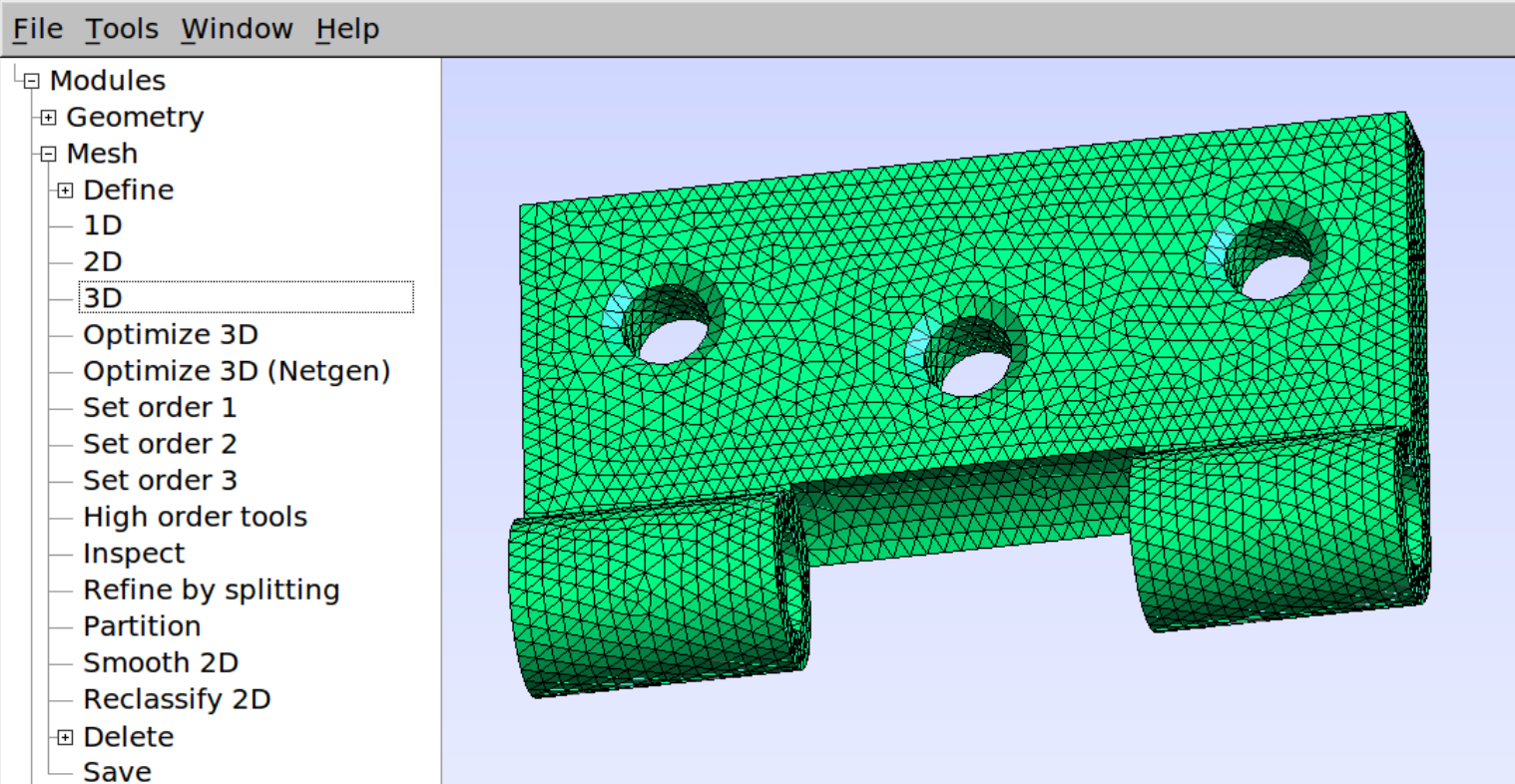

Demo 5

The mesh consists of 2967 tetrahedra. It was meshed with the

Netgen subprogram within Elmer, using a default ‘h’ value. It was

translated to .msh format by e2aps and then opened in Gmsh and

saved as a .vtk file. (See references.)

The three elements with the lowest quality rating are shown. All 9

nodes comprising these elements are surface nodes. |

|

|

| In view of the

above situation, it is obvious that Lifted cannot alter the Edge

Ratio quality level. |

|

|

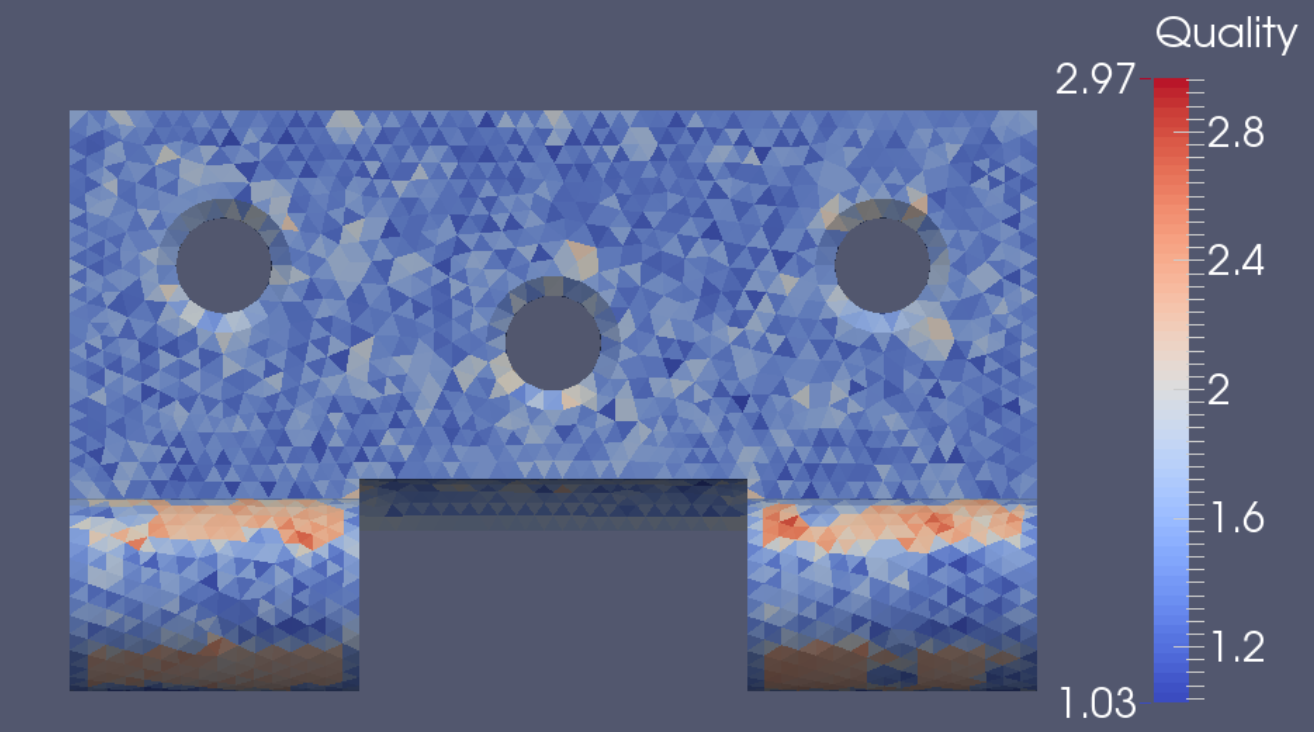

Demo 6

The next demo continues with the hinge mesh, but at a higher

resolution, with ‘h’ value set at 1.0 during its construction. It

consists of 41,211 elements and 7777 nodes.

For the two sample defective elements shown at right, no surface

nodes are present. |

|

|

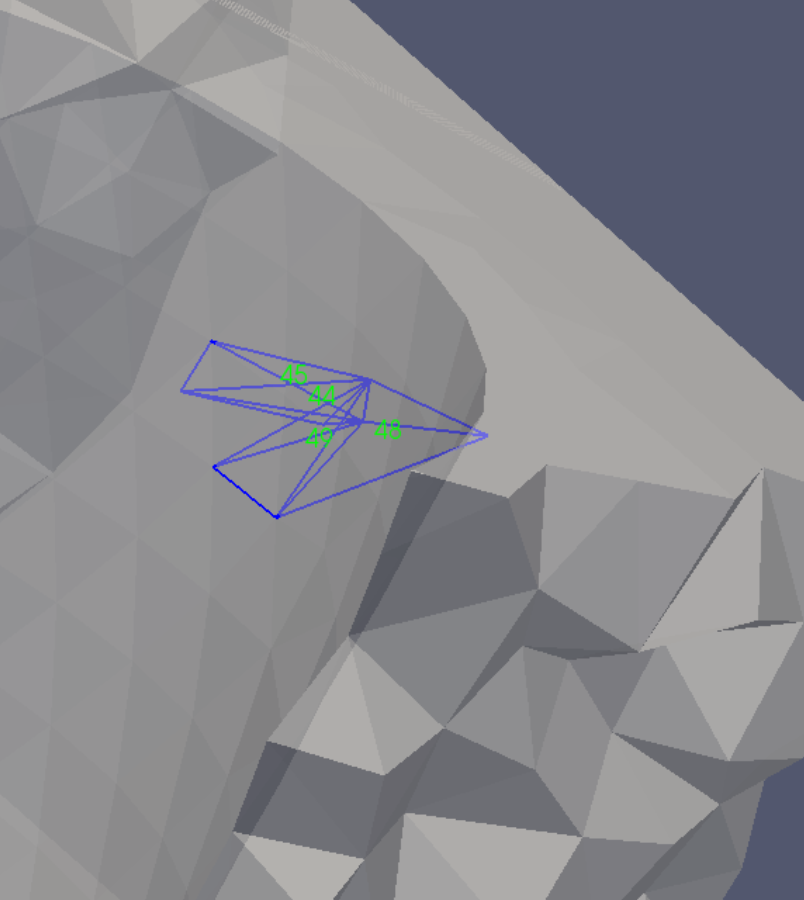

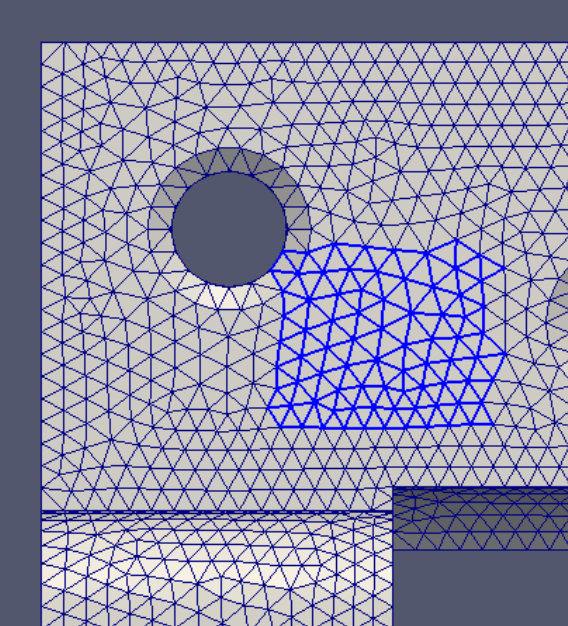

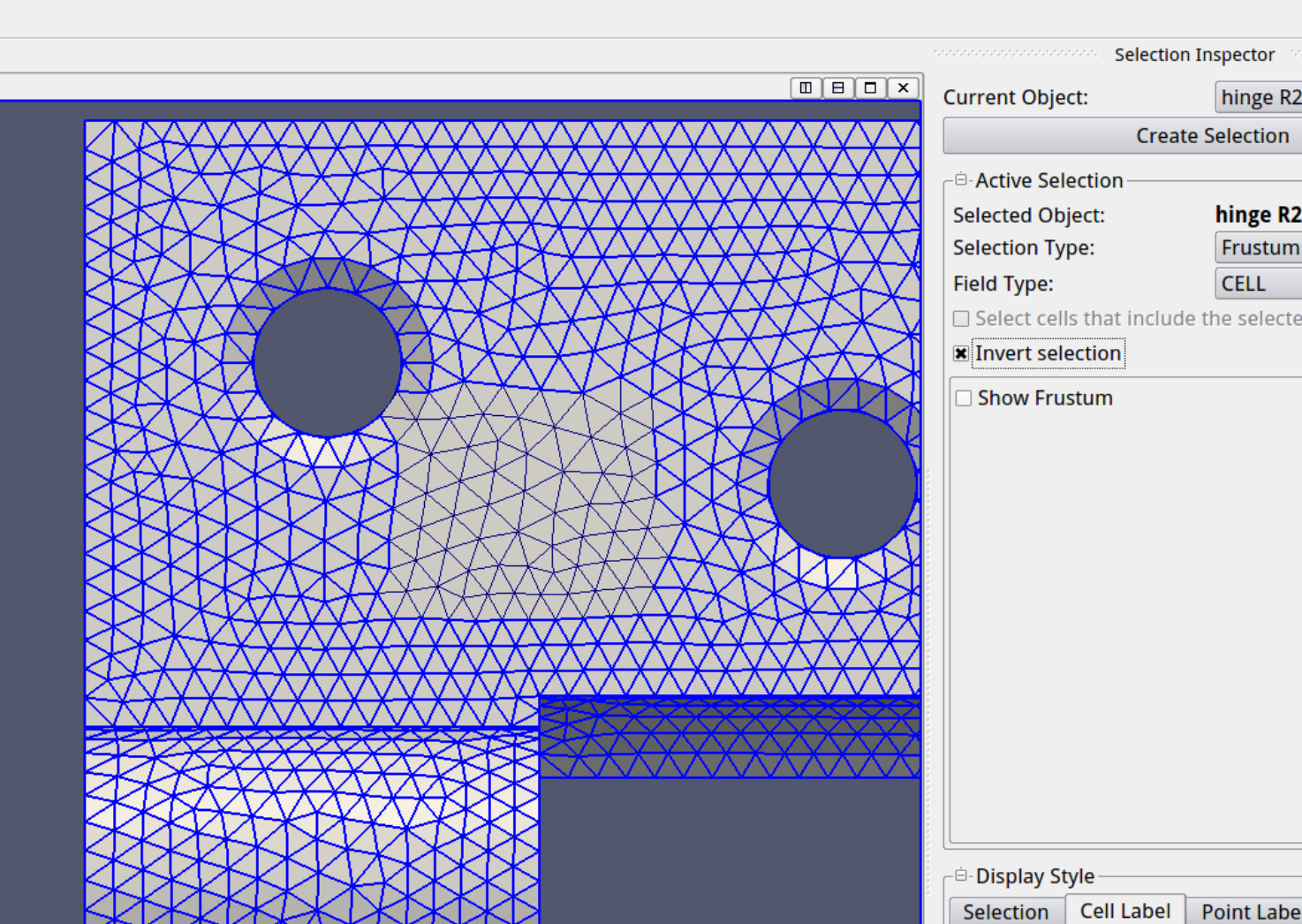

The green

element labels in the Paraview view at right show the locations of

the elements of interest when seen in a plan view. Lifted becomes

sluggish − to the point of unusability − when working on mesh of

higher density. Therefore we demonstrate how to split the mesh to

speed things up.

The arrow in the pic is pointing to the Paraview (version 4) icon

for ‘Select Cells Through’. This drills through a mesh, capturing

all included elements, resulting in the selection shown below

right.

|

|

|

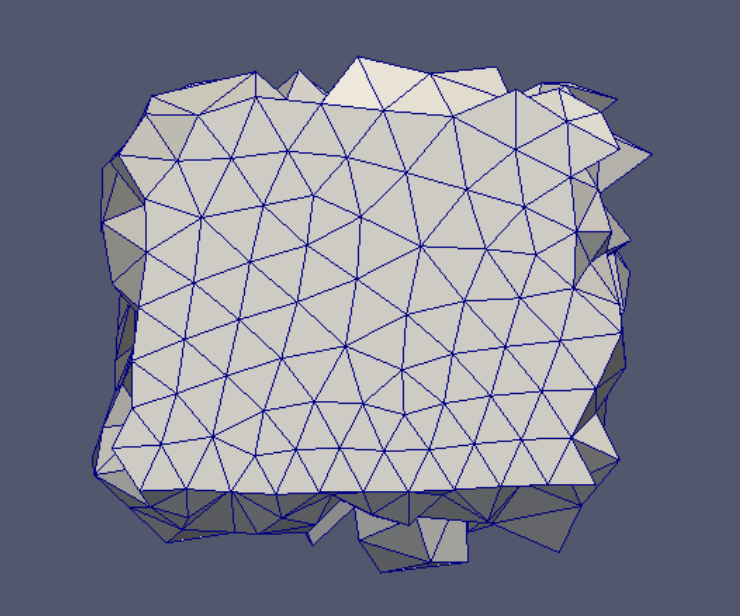

| Next we use the

‘Extract Selection’ filter, obtained through the Filters menu, to

break off the selection into a separate chunk, shown right. |

|

|

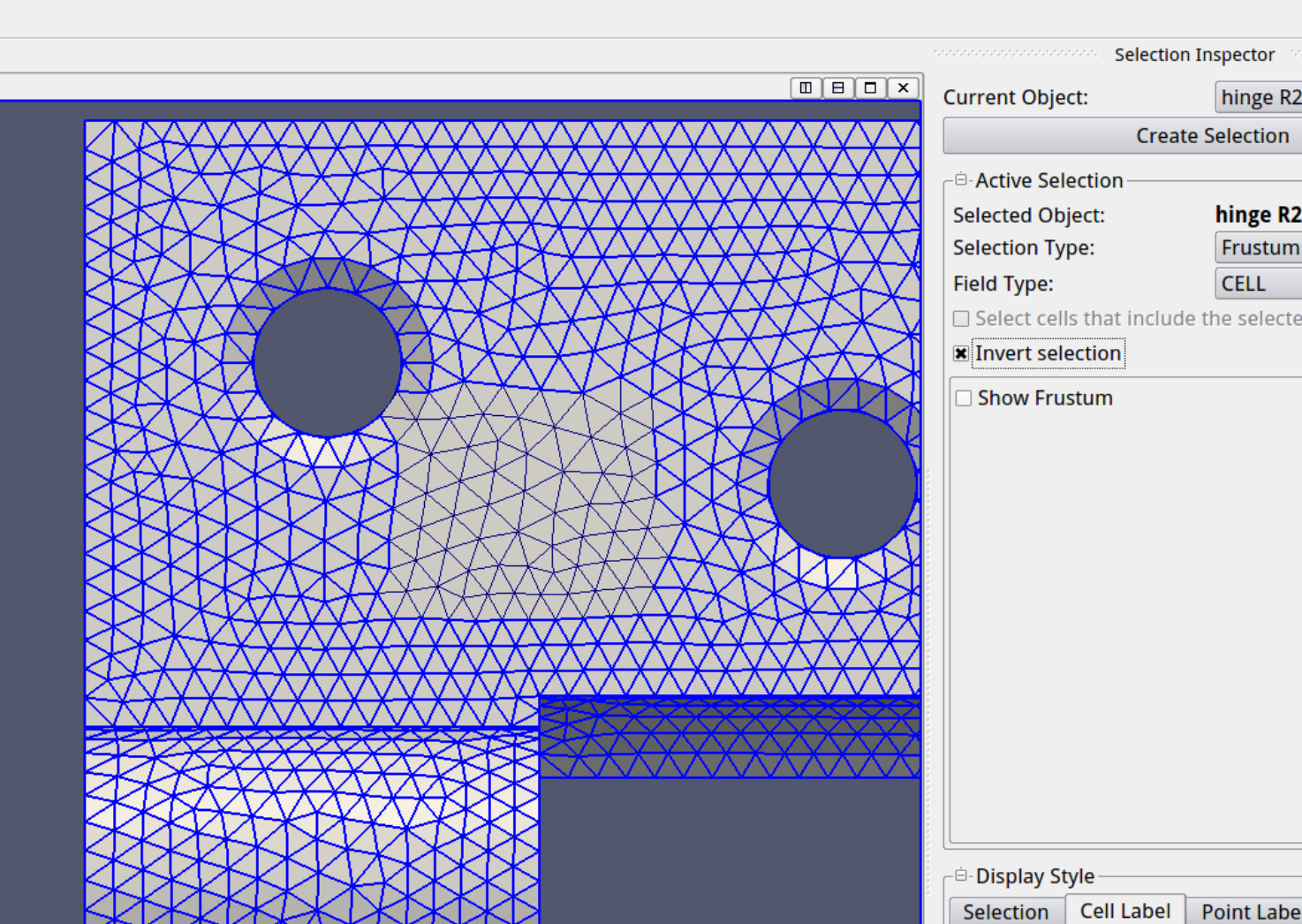

Paraview version

4 has the Selection Inspector, and from it we invert the

selection, thereby capturing all the elements which were not in

the original extraction.

We employ the Extract Selection filter once again on the parent

mesh. Now we have two pieces. |

|

|

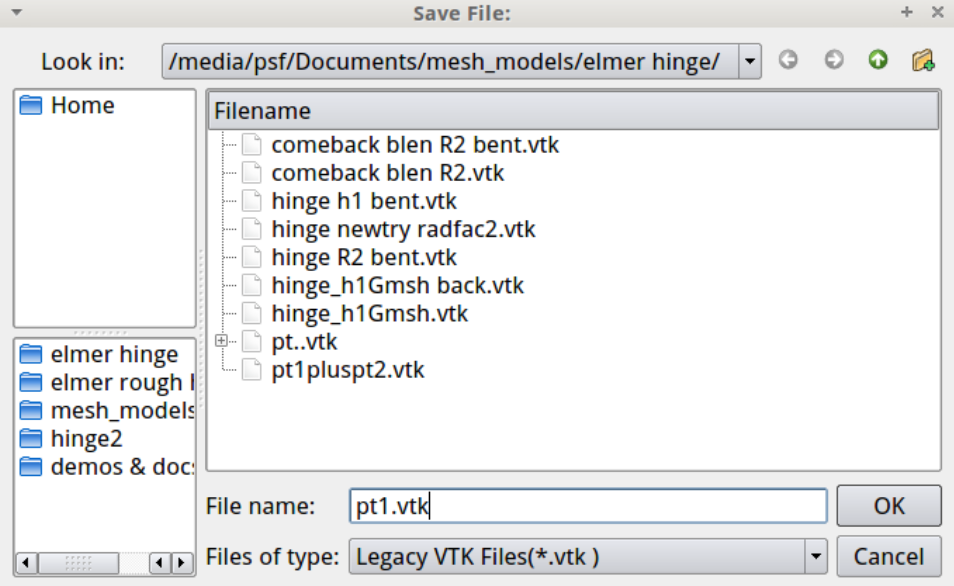

| We make sure

that the first chunk of elements is the only object selected or

visible in the Pipeline Browser visible at the left side of the

screen. Then the File⇒Save Data menu selection brings up a dialog

box, in which we choose to save a Legacy .vtk file type. After

saving the working chunk, we save the parent chunk in the same

way. |

|

|

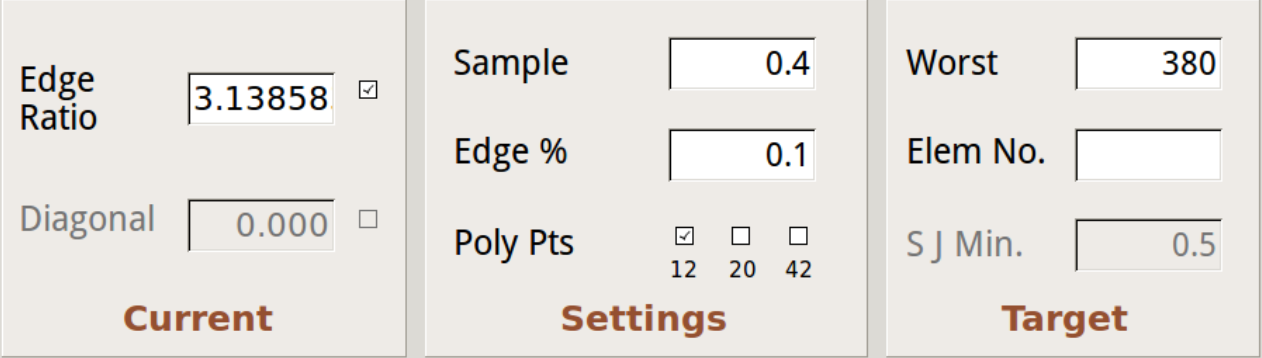

| We now open the

small chunk in Lifted. The Lifted operating panels for the small

chunk are shown right. The settings shown produce a considerable

improvement. Note that the element numbers do not correspond with

the original numbering system, which referred to the pre-breakup

model. Also note that because Lifted does not tamper with exterior

nodes, there is no glitch or discontinuity when we put the two

chunks back together. |

|

|

| We use the

File⇒Clear option in Gmsh to clear the deck, then load the

modified small chunk. We now use the option Merge under the File

menu to bring in the parent chunk. The geometry matches perfectly.

We press the 3D meshing button just for luck and then save as a

.vtk. |

|

|

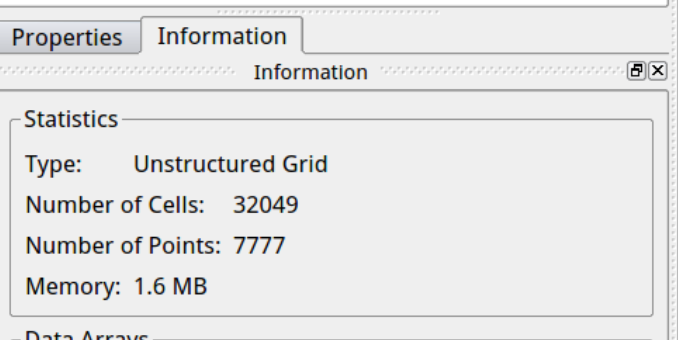

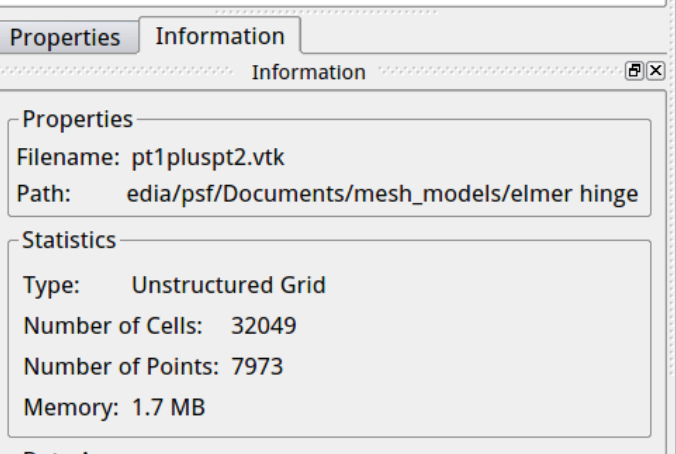

| We open the

composite mesh in Paraview again. Everything looks fine, but on

consulting the Information tab below the Pipeline Browser we

notice that the exterior nodes in the small chunk did not get

merged in Gmsh with those of the parent chunk. Not a problem, we

simply use the Clean to Grid filter and the duplicate nodes are

absorbed, giving us the exact number of nodes we started with. |

|

|

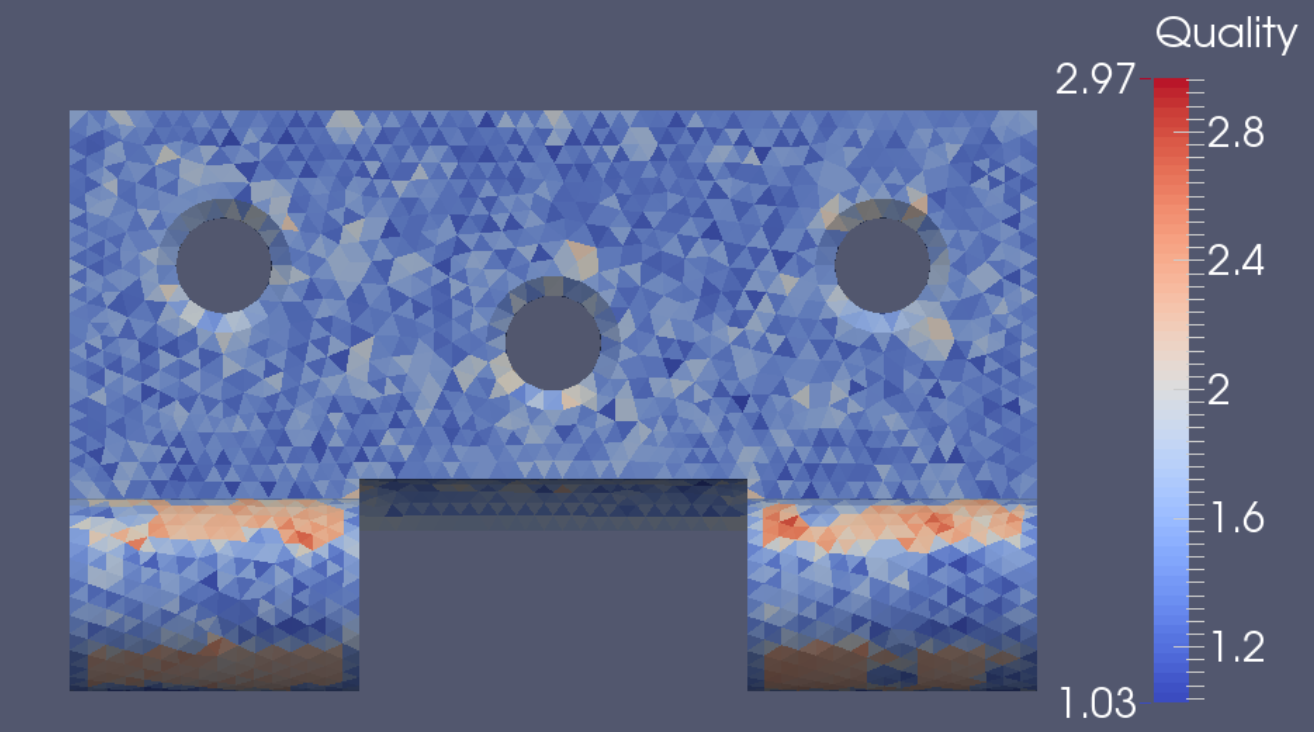

| The composite

mesh Edge Ratio quality shows the influence of the improved small

chunk. The unimpressive score of 2.97 is due to an element or two

in the parent chunk with unluckily placed surface nodes. |

|

|